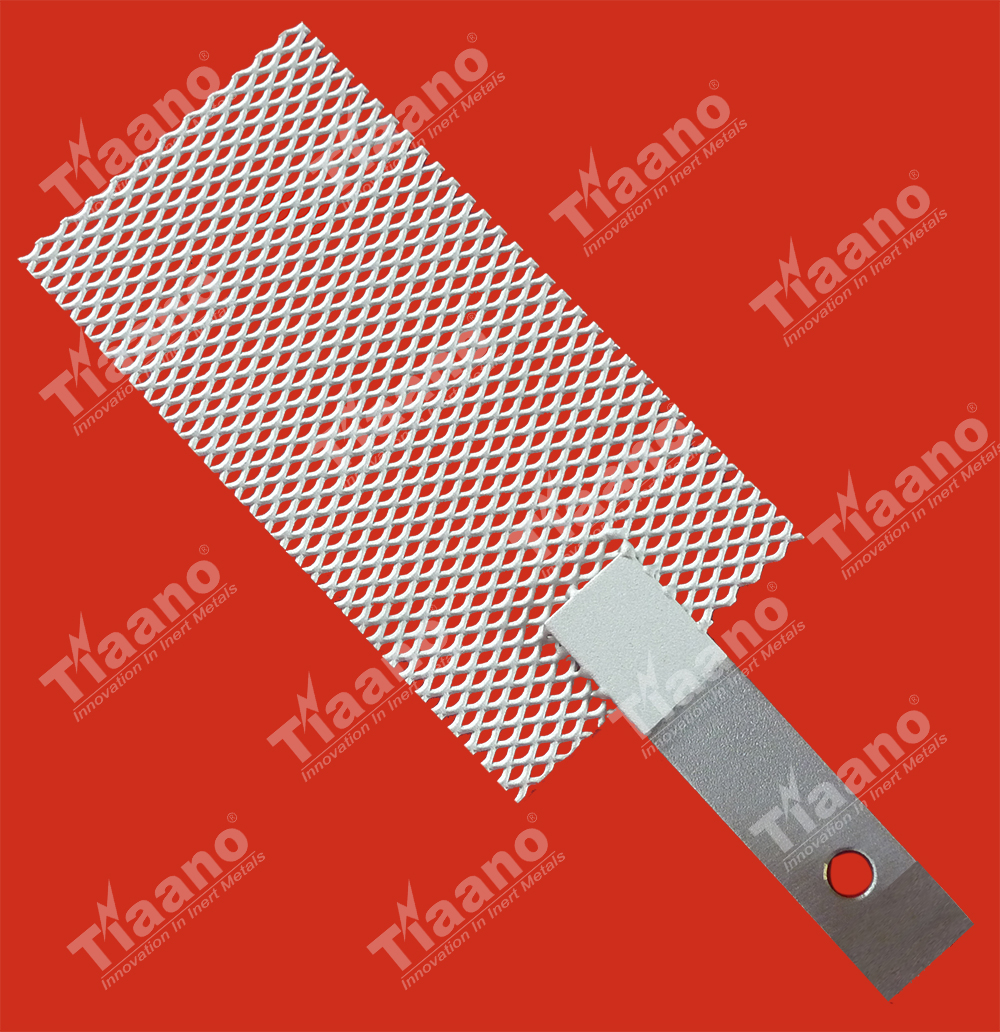

Platinum is a precious metal having very good physical and chemical properties. Tiaano manufacturing and supplying platinized anodes are widely used for electroplating and electro winning industrial applications. Electroplating is used in a variety of industries for coating metal objects with a thin layer of a different metal. This electrochemical process requires anodes. There are as many types of anode compositions as there are applications. Platinized Titanium and platinised Niobium Electroplating anodes offer numerous benefits.

Electroplating anodes are used to create products in many industries, including the hydraulic industry. The most common uses for electroplated products are chrome-plated oil pump auger flights, hydraulic cylinders, conveyor flights, sheets and tanks where it would be impractical or too expensive to make the item entirely out of the plating metal.

What is Electroplating?

Electroplating is used to coat certain metals with a thin layer of a pure metal, like silver or gold, copper, zinc or any of several alloys. During the process, an electric current passes through a solution known as an electrolyte. The composition of the electrolyte depends on the desired coating. The item being electroplated (cathode) is immersed into the electrolyte solution, as is the plating anode. The two are then connected to an electrical current source, by connecting the positive end to the plating anode and the negative to the item being to be plated. Once current flows through the system positively charged metal ions become attracted to the negatively charged item, thereby coating the item with the desired finish.

The various field are using our platinized metal Anodes for Chrome Plating, Wheel Chrome Plating, Chrome Plating Kits, Alloy Chrome Plating, Plastic Chrome Plating, Nickel Plating, Gold Plating, Silver Plating, Silver Coating, Chrome Plating Bath, Nickel Plating Bath, Bright Chrome Plating, Bright Nickel Plating, Plating Service, Tin plating, galvanized, anodized, corrode protection etc…