Titanium anodes are mainly used in the two industrial sectors of electrochemistry and electrometallurgy. Electrolytic industries using metal anodes include: chlor-alkali industry, aluminate production, water electrolysis, hospital Effluent Treatment, sewage treatment, domestic water and food utensils disinfection, industrial water treatment, steel plate galvanized chrome plating, electrodialysis desalination, seawater, batteries Production, cathodic protection, etc. Applications include chemical, metallurgical, water treatment, environmental protection, electroplating, electrolytic organic synthesis and other industries.

Advantages of Platinised Titanium Anode - Application wise:-

Electro Plating: Platinised Titanium Anodes protective to different surrounding conditions and are also resistive to corrosion. They can be resistive to moisture and steam and also to the corrosion due to oxidation and reduction. They can also withstand easily under the attack of acids and other chemicals. They can also resist the adverse effect occur at extremely high temperature.

Cathodic Protection: Combining Platinized Titanium / Platinized Niobium for Outstanding Corrosion Prevention, Advantage of platinized titanium anode in ICCP Application Effective Cathode Protection (Medium in Seawater, Freshwater, Coke Breeze, Soil, Sand etc..), environment-friendly, high current density, High anti-corrosion property & lasting working life, Keep the operating voltage stably, Small size & lightweight, Recoatable & Repetitive titanium material.

Chlor-alkali / Caustic Soda: In the chlorine gas industry produced by diaphragm method, the metal anode is resistant to chlorine and alkali corrosion. In the production of chlor-alkali, after using titanium anode, the product quality is high, the purity of chlorine gas is high, CO2 is not contained, the alkali concentration is high, and energy consumption is saved.

Chlorate and perchlorate production: Platinised Titanium Metal anode, the high temperature and high current density operation of the chlorate electrolytic cell becomes possible.

Sewage treatment, Waste Water Treatment Unit (Electrocatalytic Oxidation Technology): Oxygen evolution potential ≥1.70v, strong oxidation, High current efficiency, Insoluble anode, corrosion-resistant, Anodic matrix reusable, Low cost, long life span, cost-effective etc… Degrade stubborn or toxic contaminants. Fully automatic operation, simple process, Suitable for high salt load, No sludge, no pollution transfer, Degrade COD, decolorize, Inactivate and sterilize.

Water Treatment (Disinfection of Water to produce Chlorine): Compact Chlorinator Cell Design, Both reverse polarity and normal polarity, Self-cleaning system.

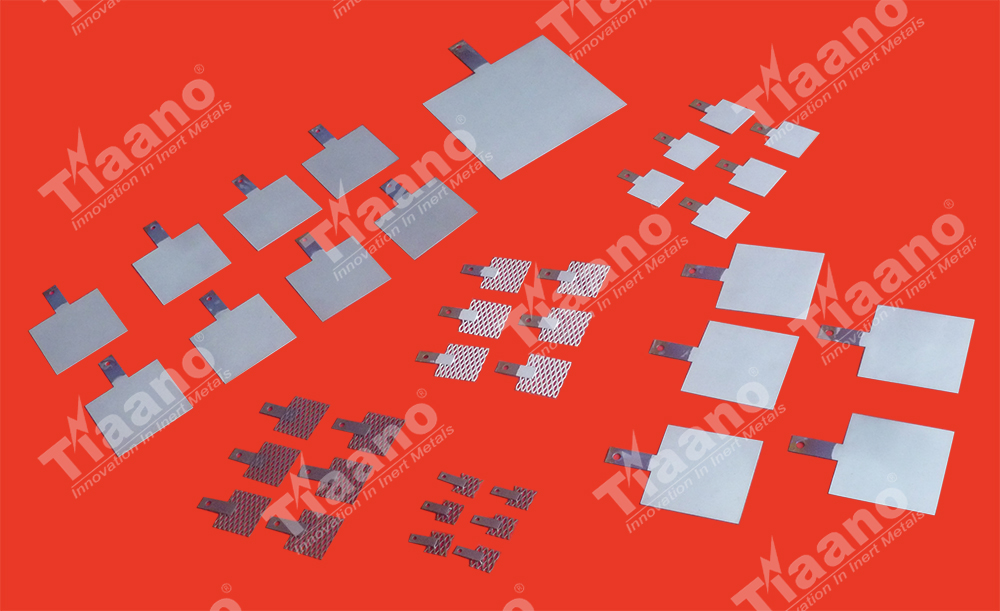

Water Ionization: The Platinised Titanium electrodes create the ionization, the electrode cell is the heart of an ionizer. It consists of a series of electrodes (plates), each separated by a membrane. The Platinized Titanium Mesh Anode is mostly used, because it has outstanding practical performance, such as strong ability of ionization release, good exchange of electrolyte, close structure and light weight, etc.

Marine Growth Prevention System (MGPS): Platinised Titanium Anode for used to make Marine Growth Prevention System (MGPS). The Marine Growth Prevention System (MGPS) was conceptualized and created with the sole purpose of defeating Marine Growth right at its very root, preventing even the most minute trace of marine organism from depositing itself along the ship’s interior altogether.