Electrochemical process requires anodes. Mainly Platinized Titanium or Platinised Niobium Anodes. Platinised titanium anodes combine the excellent electro chemical characteristics of platinum with the good corrosion qualities of titanium.

Platinised titanium is titanium that has been plated / coated with a very thin layer of platinum, normally by electro deposition process. The purpose of it is to provide a conducting medium that will not react with electrolytes. Platinum is very inert and doesn't readily react electrochemically, so you can do some very good electrochemistry with it. Titanium is used because of its high conductivity and ease in plating under electro deposition process. Furthermore, if the platinum is porous and the titanium is exposed, the titanium will passivate and soon stop interfering with any electrochemistry going on at the electrode.

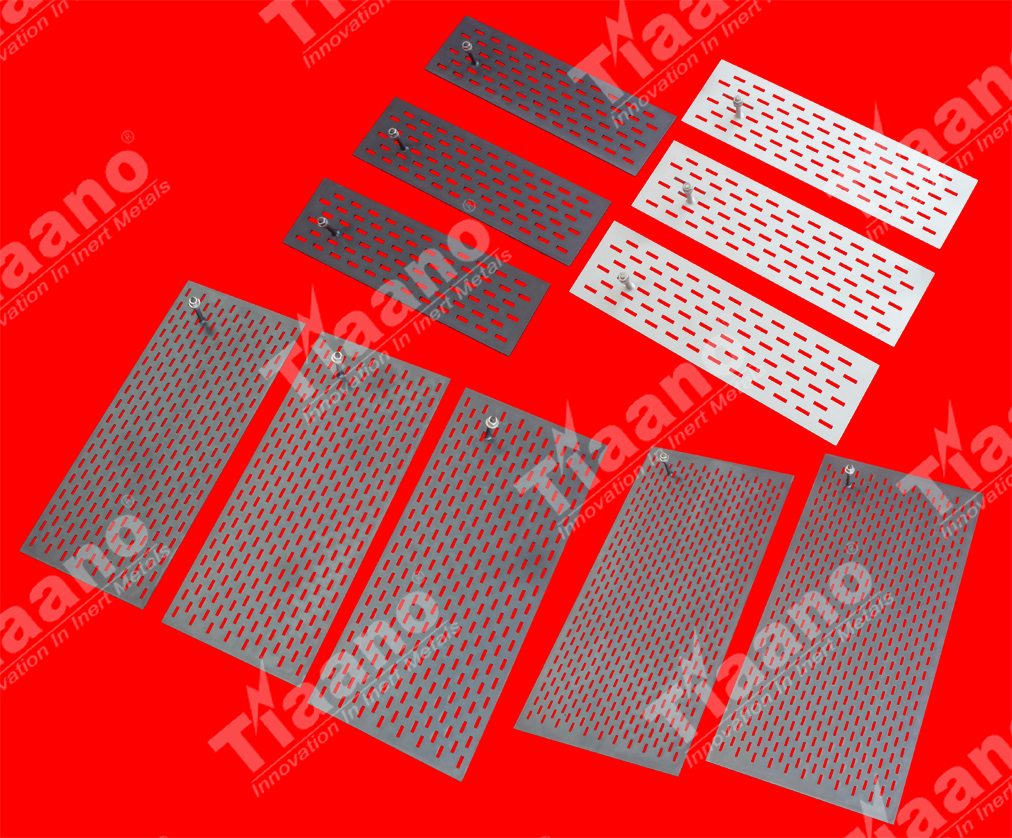

Titanium - activated by a platinum or a mixed metal oxide (MMO) layer with semiconducting properties - forms an insoluble anode. Both types of anodes are widely used for very different electrochemical applications (electro winning, electro synthesis, electro analysis, electroplating (mainly Automobile parts plating anode, Copper foil plating anode, Hard chrome plating anode, Rotogravure cylinder plating anode, Chromium plating anode, Wire plating anodes, Copper plating anodes, Gold plating anodes, Nickel plating anodes) cathodic corrosion protection (ICCP) (Mainly seawater and limited space area), disinfection (mainly Electro Seawater Chlorination, Ionization) Gray Water Treatment, Sewage Treatment and waste water treatment, Effluent Treatment and others). The property of titanium to passivate when anodically polarized is the reason for its use as anode base. The activation must be corrosion-resistant against the electrolyte and must remain active.

Tiaano suggest the platinized Titanium anodes for electro Chemical process because of its advantages like complex shapes is possible, Long lifetime, Easy maintenance, High dimensional stability and loading capacity, Good corrosion resistance, Low weight, Perfect current and distribution, Replatinizing with crediting of residual platinum etc…