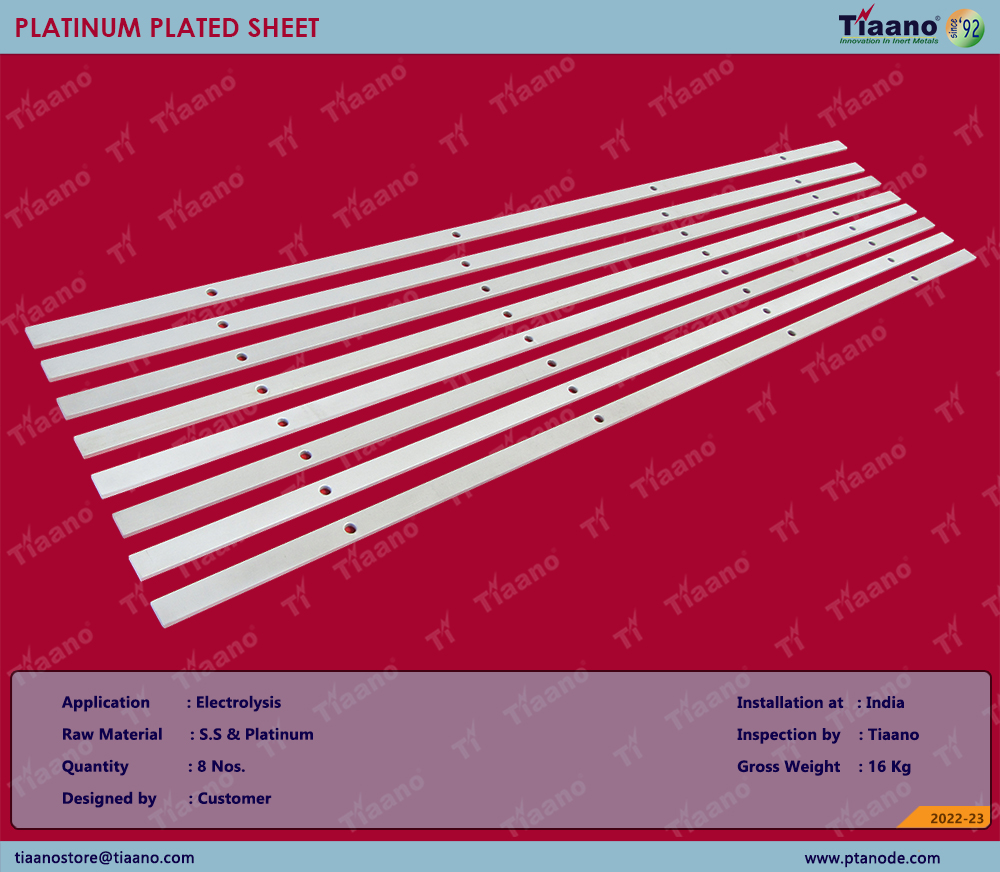

Platinum is one of the valuable metals. Platinized titanium anodes are broadly utilized in Electro Plating, metal finishing, metal recuperation processes. They have effectively supplanted lead anodes in electroplating applications because of their lower utilization, layered exactness, capacity to frame exact store thicknesses on wanted mathematical shapes, unsurprising plating science and simplicity of upkeep. These anodes can be planned and framed with different calculations in light of the parts to be electroplated.

Why is platinum used as an anode?

Platinum is used on the surface as a primary anode material due to its excellent corrosion resistance under anodic conditions coupled with its ability to pass current in all electrolytes without forming an insulating film. The corrosion resistance of platinum manifests itself in its low consumption rate.

Why is platinum used as cathode?

Platinum is used in electrochemical cells because it is resistant to oxidation- it will not easily react, which makes in excellent as an electrode as it will not take part in the Redox reactions occurring in electrochemical cells.

What is platinum electrode made of?

Generally, Electrodes are made of platinum 10% Iridium alloy for added mechanical strength which ensure long period of trouble free service. Electrode cylinders are usually made of wire gauze having wire diameter 0.15 mm * 360 mesh per cm2.

Interesting Facts about Platinum:

· Meteorites and our moon contain a higher percentage of platinum than can be found on the Earth.

· The melting point of platinum is 3,215 °F (1,768.4 °C) and the boiling point is 6,917 °F (3,825 °C).

· Typically 95% pure, platinum is one of the purest precious metals.