Ti Anode Fabricators Pvt. Ltd is ISO 9001:2015 certified company. Along with this credentials and our dedicated, experienced, and professional staff makes Tiaano the most recognized and qualified anode manufacturer. Tiaano, we are a manufacturer of Titanium based anodes and cathodes for Electro Chemical process, electrolysis process specially ionization process.

Why Platinum Plated Anodes needed for Ionization Process?

Platinum is a catalyst, and is needed to speed up the electrolysis. With the water ionizers changing the water so drastically just by passing the water over the electrodes, the ionization process wouldn’t occur without a speeder-upper.

The Platinised Titanium electrodes create the ionization, the electrode cell is the heart of an ionizer. It consists of a series of electrodes (plates), each separated by a membrane. The Platinized Titanium Mesh Anode is mostly used, because it has outstanding practical performance, such as strong ability of ionization release, good exchange of electrolyte, close structure and light weight, etc.

Our Product Range for Ionization Process:-

Platinum Plated Mesh Anode and Cathode

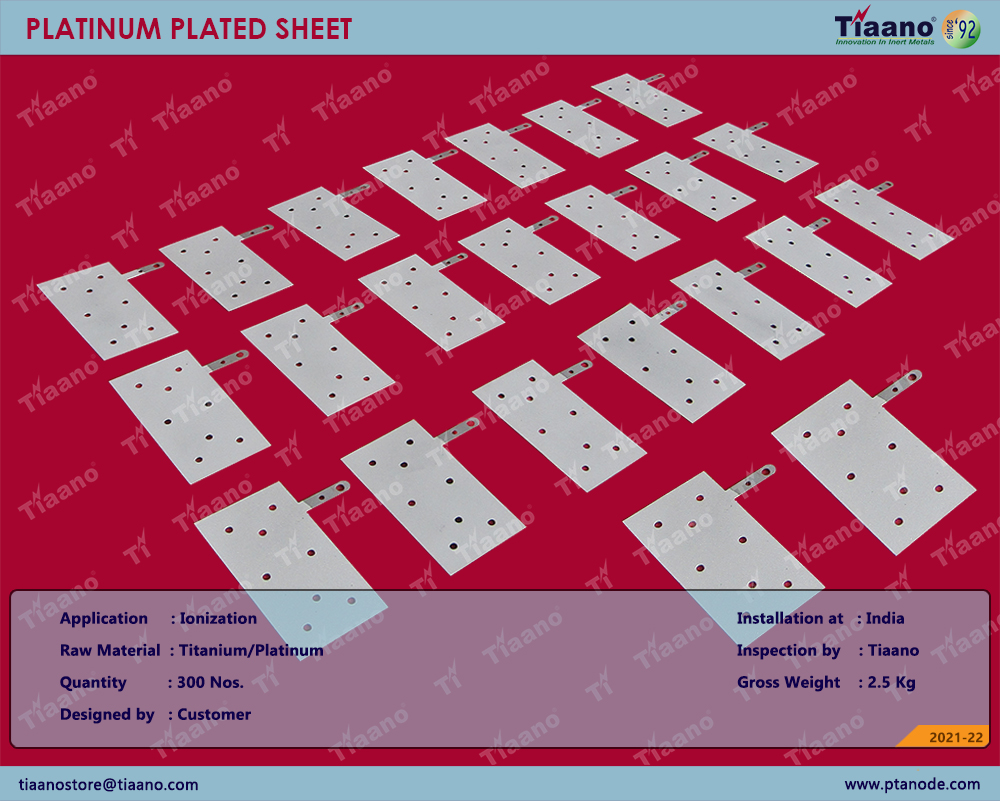

Platinum Plated Sheet Anode and Cathode (Perforated, Holed, Profile Cutting)

Platinum Plated Tubular Anode and Cathode

Platinum Plated Rod Anode

Platinum Plated Customized Anodes and cathodes (As per customer Drawing)

You may refer more details from here:-

Facebook Page, Instagram Page, Twitter Page, Pinterest Page