Ti Anode Fabricators Private Limited was established in the year 1994 as a sole proprietorship company. Since then, we are engaged in manufacturing, exporting and supplying a comprehensive range of Anodes, Electro Chlorinators, PlatinisedTitanium Anode and Cathode for Electrochlorinator, Chlor Alkali Chlorine Anodes, Cathodic Protection Anodes, Thermowell Sensor, Cooling Tower Water Treatment, Anodes and Cathodes, Heat Exchangers and much more. We also offer Welding and Coating Services.

ISO 9001:2015 certified, Manufacturer of anodes made from Titanium, Niobium and Tantalum. Available in various sizes. Capabilities include design, fabrication, electro polishing and Electro Plating or Electro Deposition.

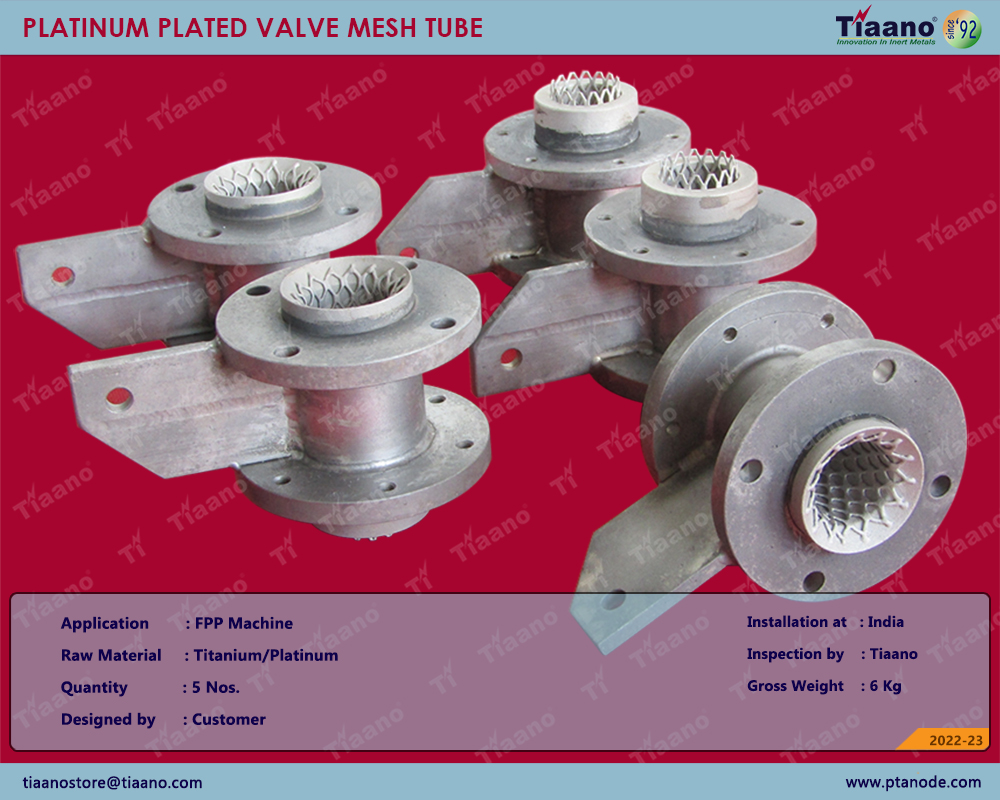

Suitable for Hard Chrome Plating, semiconductor, valve manufacturing Rotogravure plating and other applications.

Some of the advantages of platinized titanium anodes:

Increased throughput with reduced plating times

Reduction or elimination of secondary processes, such as grinding

Anode geometry remains constant over time

Long operating life and Low maintenance

Higher bath life and Energy savings and light weight

Feature of the Platinum Plated Anode:-

Platinised titanium / niobium anodes are having the features

Low weight - good current resistance, Long life operation, maintenance free, Economical – due to low platinum requirements.

High dimensional stability and low resistance, highly suitable as anodes of custom made shapes.

Visit our site to know more about platinized titanium, niobium, tantalum and molybdenum anodes.