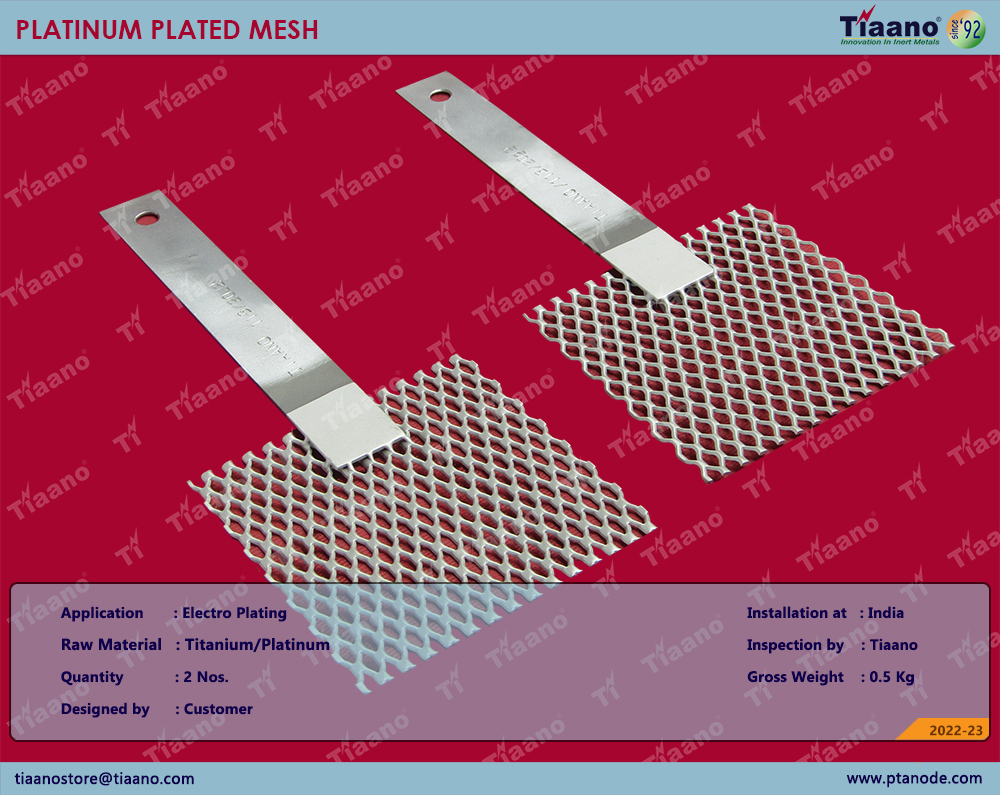

Platinised Titanium Mesh Anodes are made out of titanium mesh substrate with a platinum layer plated on it. Platinized titanium mesh anodes are planned with explicit platinum material (Pt) which makes the anodes correspondingly stable for a long time. Tiaano design and fabricating platinised titanium mesh anodes with various aspects and plating thicknesses. Tiaano have the lab to do platinum plating 0.5 micron to 20 micron thick by the course of Electro testimony.

Tiaano Platinized Titanium extended Mesh Anodes are utilized in different applications. Tiaano have the plating bath to get ready Platinised Titanium , Platinised Niobium and Platinised Nickel combinations. We have the inplant creation limit of 20 m2 each day. We are trading the anodes in excess of 64 nations.

Benefits of Platinized Titanium Mesh Anode (Pt Ti):-

Platinized Titanium mesh anodes can be effectively fixed to all surfaces.

Platinized titanium mesh anode enjoys benefit being an inactive anode which don't consume and remains correspondingly stable for a significant stretch.

Even metal conveyance and of platinum layer and ideal bond on the titanium network.

Platinized titanium mesh anodes are correspondingly steady and dependable.

Platinized titanium mesh anodes have great mechanical properties

Platinised titanium mesh anode the base material is reusable after re-plating.

Platinized titanium mesh anodes requires less anode maintenence.

Platinised titanium mesh anodes are having uniform conductivity

Platinised titanium mesh anodes are having uniform current appropriation properties

Platinized Titanium & Niobium Anode (Dimensionally Stable Anode)