Tiaano, Manufacturer and distributor of chromium plating Titanium Anode, electroplating Titanium Anode and electro winning Titanium Anodes. Capabilities include Fabricating, MIG/TIG welding, heat treating, tempering, quenching, forming, laser cutting, punching, drilling, coating and plating. Serves the electroplating industry, heavy equipment, defense, water Industry etc.

Advantage of titanium Anode in Electro Plating Application:-

Titanium anode can keep stable anode-cathode distance during titanium anode service time as a kind of inert anode to ensure good quality of the final product and keep voltage stable to reduce the power consumption. For the catalytic properties of platinum group elements, big exchanged current density on the electrode surface, low oxygen evolution potential and oxide film with microstructure that treated by special technique on the titanium surface, great active area is gained on the electrode surface, titanium anode is considered to be the most suitable anode for electroplating under big current density with high speed.

Another advantage of titanium anode is titanium’s reusability. When the coating fail to work, recoating on the well-preserved titanium substrate after sand blasting and acid pickling treatment will make it reused without paying more cost for titanium substrate.

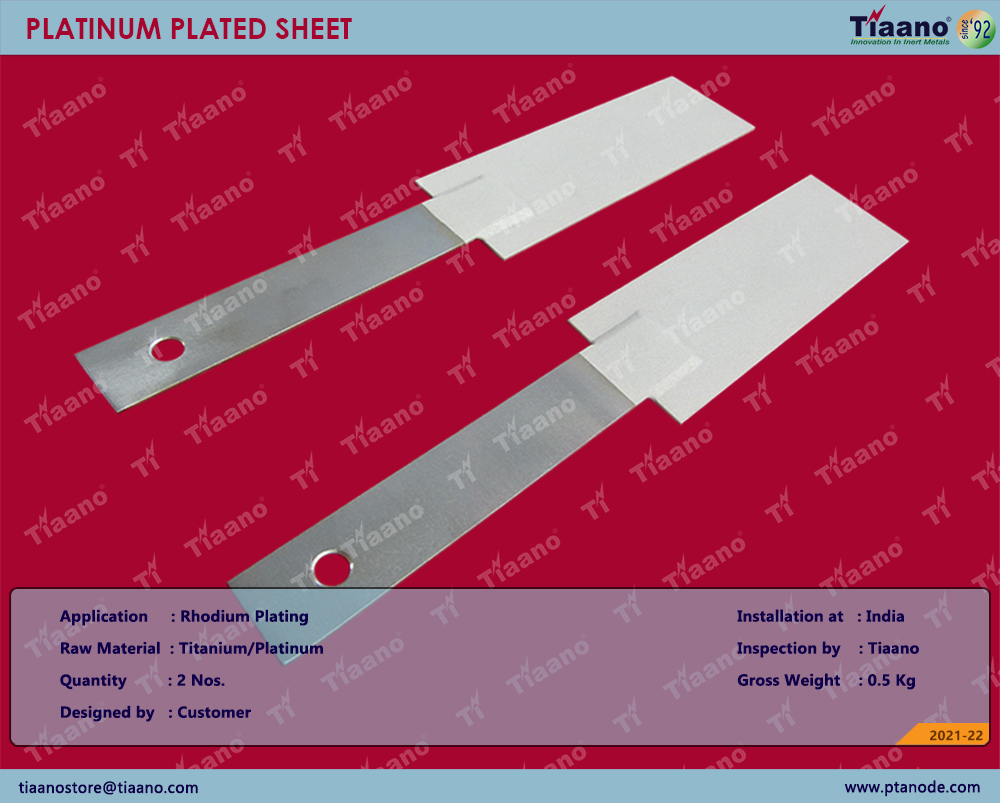

Titanium Anode for electroplating:-

Coating or Plating: Platinum – Titanium, Platinum – Niobium, Platinum – Tantalum

Field: Electroplating, Hard Chrome Plating, Gold Plating

Current density: 600—1500A/m2

Types of Anodes for Electro Plating Application:-

Platinized Titanium Anodes, Platinized Niobium Anodes, Platinized Tantalum Anodes, Platinized Stainless Steel Anodes, Platinized Zirconium Anodes, Platinized Copper Anodes