Tiaano is the manufacturer of a huge range of Titanium Anodes for Electro Plating Industry. Platinum Plated titanium anodes have been applied widely to Electro Plating, hard chrome plating applications. The anodic stability and service life are the main concerns in these applications. We have been in this field for more than 30 years and have gained in depth knowledge to deliver the products as per the exact requirements of our clients.

Parameters of platinum Plated Mesh electrode for Electro Plating:-

Substrate material: Titanium Grade.One

Electrode connection material: Titanium

Plating or Coating process: Electro Deposition process / Electro Plating Process

Plating or Coating composition: Pure platinum

Precious metal coating thickness: 1.5 - 10 µm (Micron)

Operating current density: 1500A / m2

Coating or Plating Features: Platinum and titanium substrate combined with a solid, stable performance, high output current density, long operating life

Electrode Shapes: mesh, plate, tubular, rod, wire, or customized

Platinized Titanium & Niobium Anode (Dimensionally Stable Anode)

Project Details:-

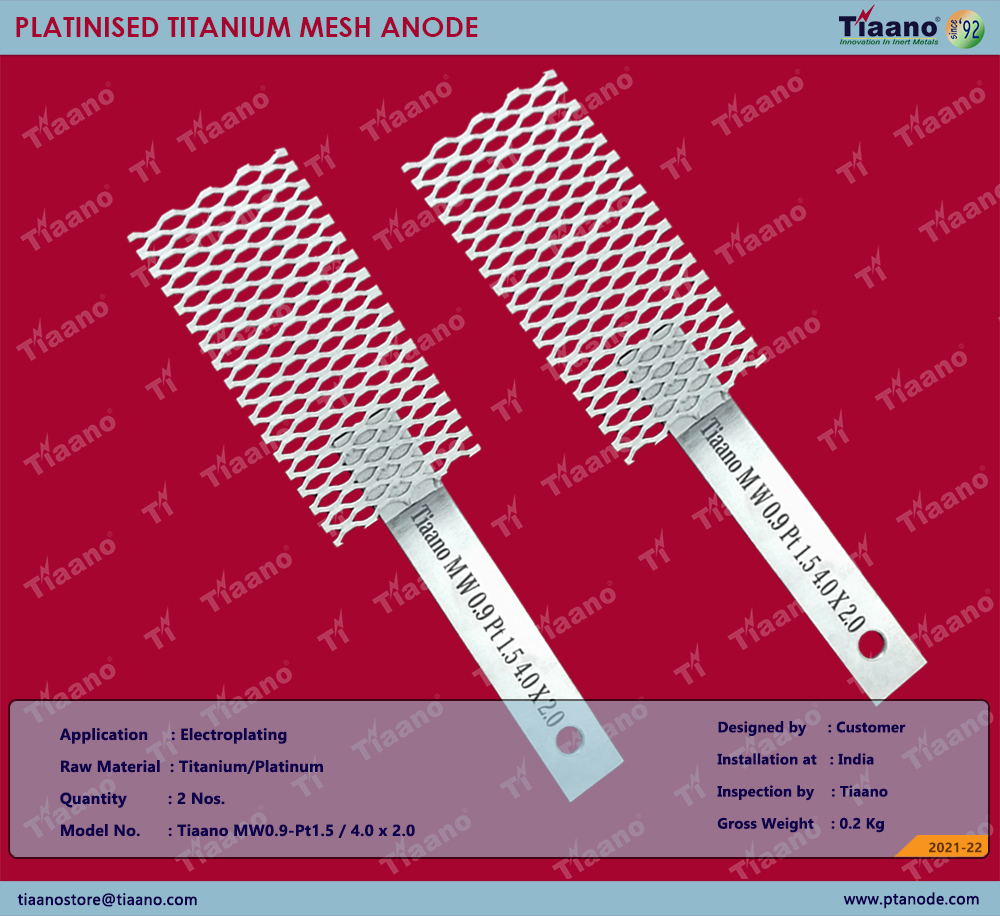

Tiaano: Manufacturer and Supplier of Platinum Plated Titanium Expanded Metal mesh Anode.

Anode: Platinum Plated Mesh Anode, Platinum Plated Metal Mesh Anode, Platinized Expanded Mesh Anode

Application: Gold Plating, Electro Forming, Jewellary Plating, Rhodium Plating

Installation at: India, Delivery through Amazon E-Commerce

Inspection by: Tiaano.

You may refer more details from here:-

Facebook Page, Instagram Page, Twitter Page, Pinterest Page