TITANIUM NIOBIUM ROD FOR HARD CHROME PLATING

September 9, 2022 at 10:25 AM

—

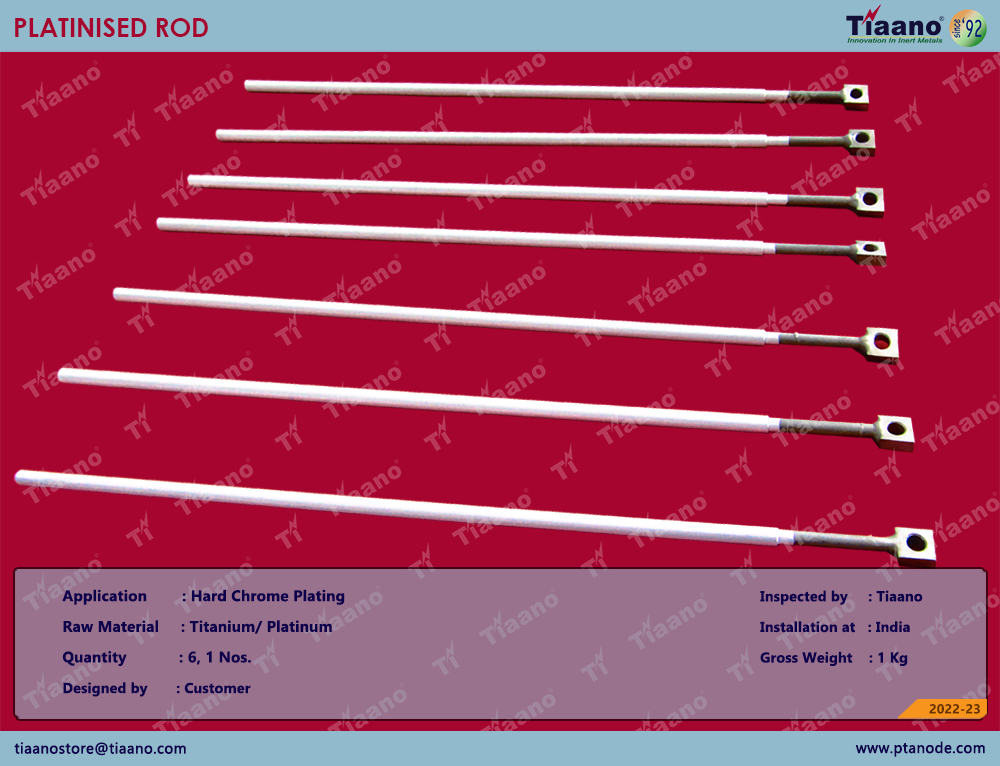

Platinised

Hard chrome plating is an electroplating process in which chromium is deposited from a chromic acid solution. Thickness of hard chrome plating ranges from 25 to 500µm.Various types of hard chrome include micro-cracked chromium, micro-porous chromium, porous chromium and crack free chromium. It is essential that the micro-cracked and porous coatings have a minimum thickness between 80-120µm in order to confer adequate corrosion resistance. Micro-cracked chromium has a Vickers hardness of 800-1000 kg/mm2, while crack-free chromium has Vickers hardness between 425-700 kg/mm2. The formation of micro-porous chromium is achieved by a specialized plating method involving the use of inert suspended particles. Porous chrome plating is developed by etching electrodeposited chromium. These are designed to retain lubricant, for sliding and bearing type applications.

The finishing processes are used to give the following improvements:

Improved appearance

Improved adhesion

Greater solder ability

Resistance to corrosion, chemicals, wear, extreme temperatures and tarnish

Hardness & Durability

Electrical conductivity

Removing of surface flaws and burrs

Control of surface friction