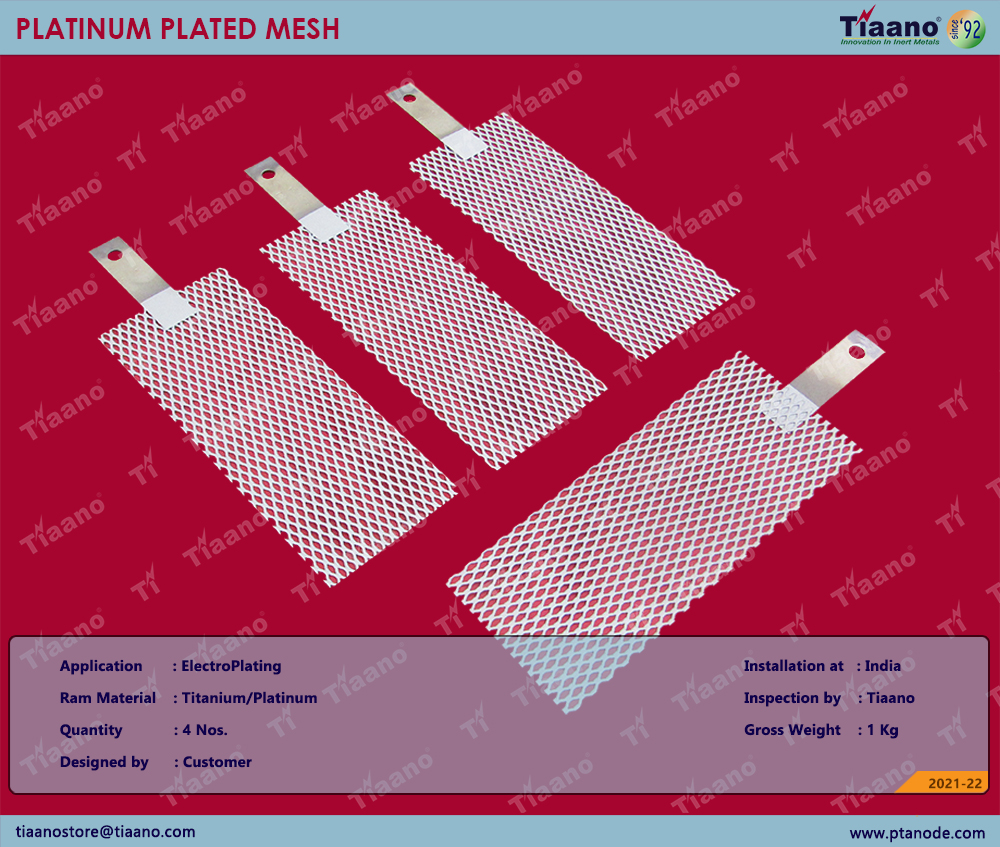

Electro Plating Titanium Anode - Platinized Titanium Mesh Anode

March 8, 2022 at 5:08 PM

—

Platinised

Tiaano manufactures Platinised Titanium Anodes for use in various applications where the electroplating of a wide range of metals is necessary. The advantage that these Titanium Anodes have over the two previous anode types and lead anodes is that the risk of additional toxic or hazardous substances being introduced into the electroplating line is eliminated, eradicating costs that arise from the removal of hazardous substances. They are also environmentally friendly and the fact that the inter-electrode gap remains constant throughout the design life of the anode means that the Platinized Titanium Anodes maintain constant voltage and product quality. Oxygen-evolving Titanium Anodes have lower anodic operating potentials and use of these anodes yields the additional advantage of the ability to re-use the anodes. Once the anodes have reached the end of their design life the necessary repairs can be made, the anodes can be cleaned and then re-coated.

The use of stainless steel anodes, although relatively inexpensive produce iron oxide (rust) as a by-product of anodic passivation and the use of graphite anodes results in an increasing inter-electrode gap as the anode dissolves meaning voltage and product quality do not remain constant. Hence platinum plated Titanium anode is the best choice for Electro Plating, electrolysis and electro chemical application.