The change from lead anodes to platinized titanium anodes was encouraged by the introduction of high efficiency fluoride-free baths, which attacked lead anodes more severely than traditional hard chrome plating chemistries. Originally lead anodes were replaced with titanium anodes that had a copper or aluminum core for high current applications, and over time the extra benefits of platinized titanium anodes were recognized.

Overview of the specifications – Platinised titanium anodes

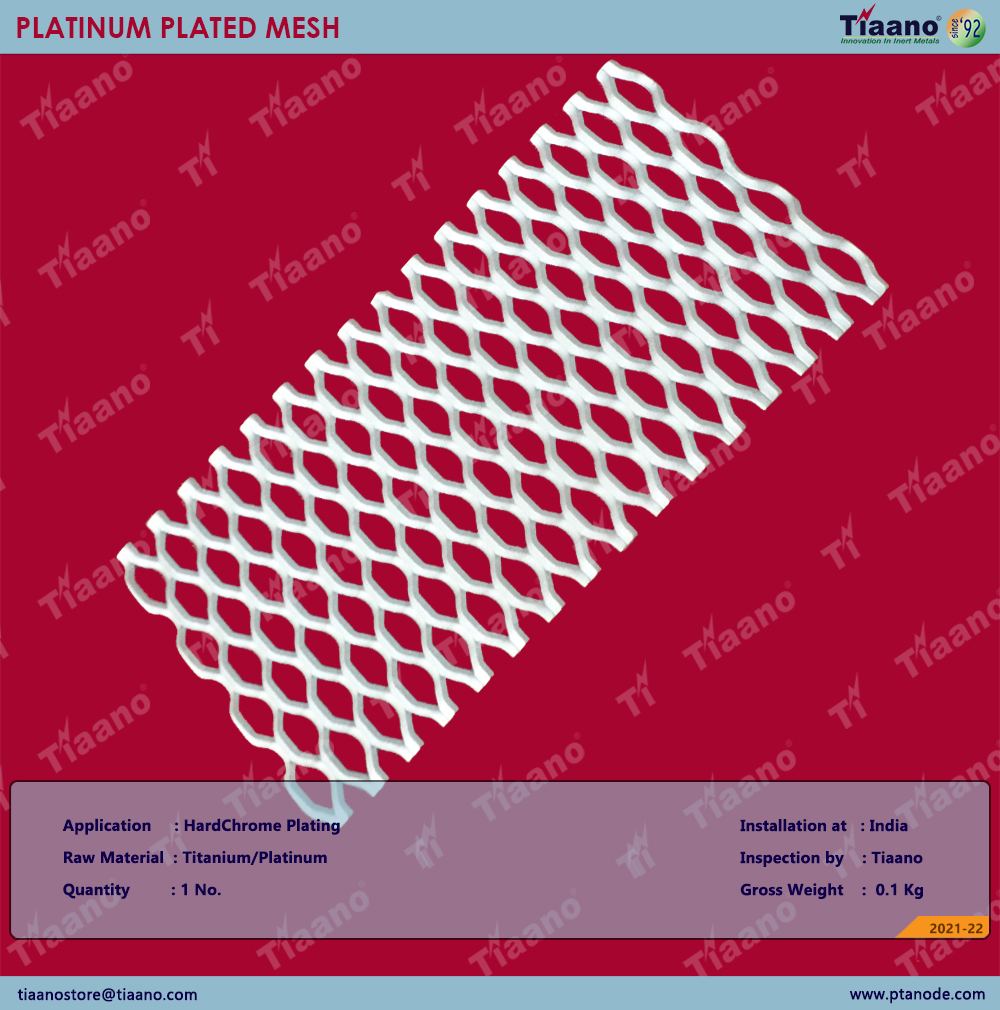

• Base material (substrate): Titanium

• Material Grade: Grade 1 or 2

• Shape of base material: Expanded mesh, sheet, Plate, pipe, rod, wire

• Size and construction: Custom Design / Tiaano Standard Design

• Platinum layer thickness: standard: 2 – 5 Micron

• Plating methods: Electro deposition / Electro Plating

• Specific current density: Max. 75 A / dm2

• Type of application: Anode / bipolar electrode

Why Pt Titanium is the best alternative to lead anodes:-

Our Titanium Mesh Anodes are low energy mesh materials to replace conventional cast or cold rolled lead anodes. The lead anodes pose a challenge for EW operations in handling and disposing of lead waste. The cells need to be cleaned by operators to eradicate lead sludge accumulation that can be risky to health and safety of an operator. Unlikely, the titanium anodes avoid this need. Additionally, the titanium anodes do not need to be stabilized by adding cobalt sulfate to the electrolyte. In titanium anodes, there is no need to electrically separate the cells that increases the plant availability and productivity.

Some of the advantages of platinized titanium anodes:-

• Increased throughput with reduced plating times

• Reduction or elimination of secondary processes, such as grinding

• Anode geometry remains constant over time, allowing consistent optimized plating results

• Long operating life

• Low maintenance

• Higher bath life