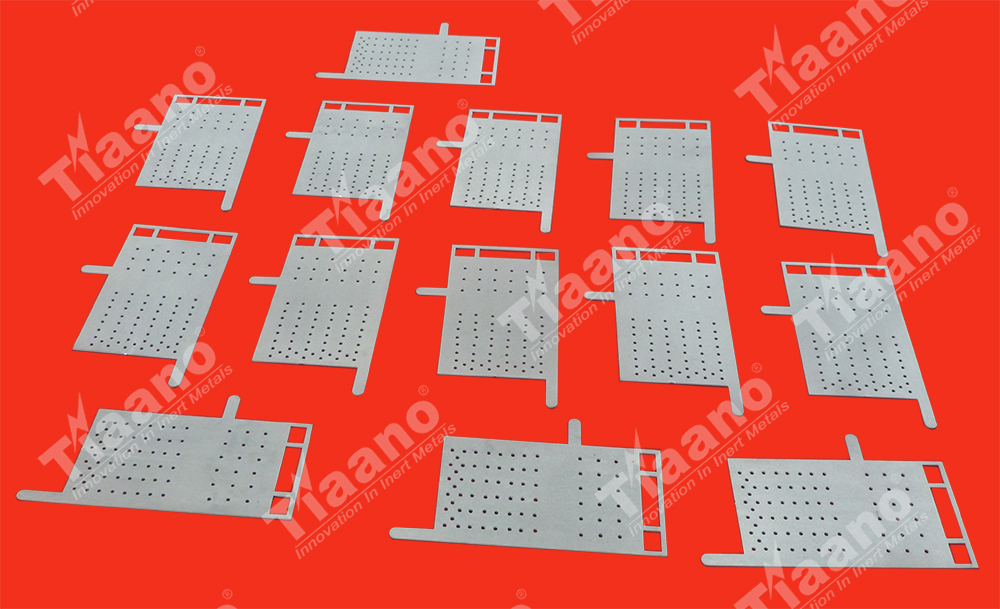

Tiaano electroplating anodes are available in an extensive selection of standard and custom shapes to fit a wide variety of plating systems / plating Baths. Tiaano manufacturing and supplying the platinized anodes (Substrate Titanium and Niobium) for various Electro plating Industries.

Key benefits for Platinized (Platinised) Anodes in Electro Plating:-

Increase anode lifetime without sacrificing quality

Maintain predictable and stable electrode position rates

A low consumption rate that conserves precious platinum.

Favorable dimensional stability.

Corrosion resistance ensures durability with easy maintainability.

Light weight, as well as favorable current distribution in electroplating.

What is Electroplating?

Electroplating is basically the process of plating a metal onto the other by hydrolysis mostly to prevent corrosion of metal or for decorative purposes. The process uses an electric current to reduce dissolved metal cations to develop a lean coherent metal coating on the electrode. Electroplating is often applied in the electrical oxidation of anions on a solid substrate like the formation of silver chloride on silver wire to form silver chloride electrodes.

Electroplating is majorly applied to modify the surface features of an object (e.g corrosion protection, lubricity, abrasion), but the process can also be used to build thickness or make objects by electroforming.

The Anode and Cathode

In electroplating practice, the current is usually introduced from an external source and the anode (Platinised Anode) is the positive electrode and cathode is a negative electrode. The cathode is the electrode where the electrochemical reduction reaction occurs. The anode (Platinised Anode) is that where the electrochemical oxidation reaction occurs.

The electroplating process uses an anode (Platinised Anode) and a cathode. In electroplating, the metal dissolved from the anode can be plated onto the cathode. The anode is provided with direct current, oxidizing and dissolving its metal atoms in the electrolyte solution. At the cathode, the dissolved metal ions are decreased and the metal is placed on the product. That is called Electro Plating process.