PLATINUM ACTIVATED TITANIUM ANODE ELECTRO DEPOSITION PROCESS

June 14, 2020 at 10:54 PM

—

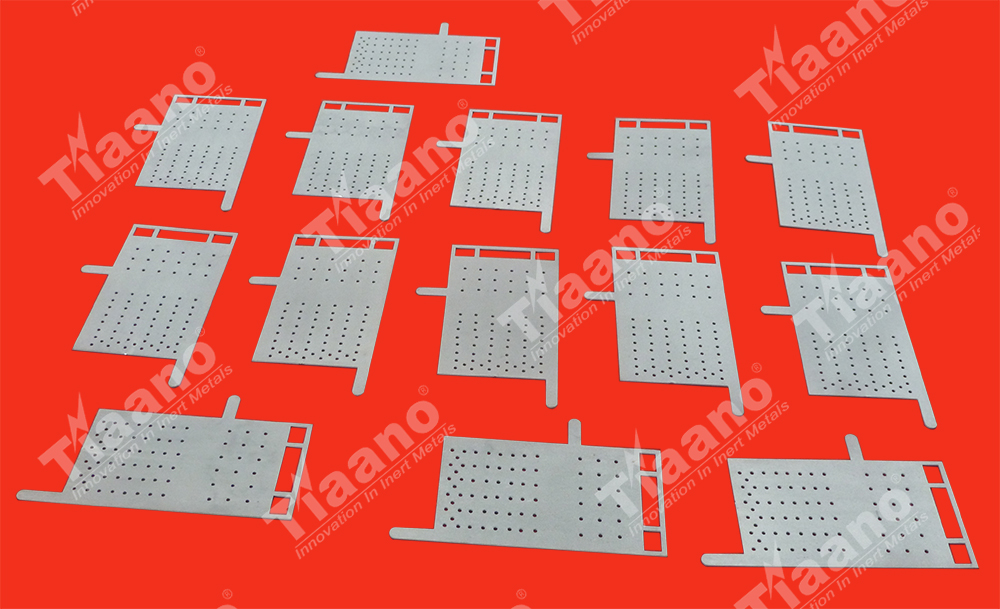

Platinised

Tiaano platinum plated/ coated anodes are mesh or Sheet designed for use in electro plating / electro deposition baths for Rhodium Plating and or acid-based Gold solutions. The platinized Titanium mesh or sheet anodes comes with a stem are suspended in plating baths with the mesh portion immersed in the electroplating solution.

The electroplating process consists of the immersion of an object to be coated in a bath containing an anode. The object itself functions as the cathode. The bath is usually an aqueous solution of salts of the metal to be deposited. An electrolytic cell is produced when voltage is applied to the anode. The cathode being negative. Metal ions formed in the solution are attracted to the cathode where they gain electrons and deposit out of the solution onto the cathode surface as pure metal.

Benefits of Platinised Titanium Anodes for Electro Plating or Electro Deposition

Long life, dimensionally stable and easily fabricated into any shape

Homogeneous and long-lasting active surface

Energy savings with shaped anodes and small anode/cathode distances

Reduced environmental burden and reduced maintenance

Mesh anodes provide excellent throwing and can be used at high current densities

Easier handling and recoating

Considerations when converting from Lead to Platinised Titanium anodes

The service life of platinised titanium depends on both the electrolyte matrix and the applied current density. Therefore, in fluoride containing baths and at current densities >75 A/dm2 platinised niobium is recommended in preference to platinised titanium. For most applications the platinum wear rate is very low and the corresponding anode life time high. In sulphuric acid chromium baths the platinum consumption is between 1g and 4g platinum per million amp hours. Careful design of the platinised anodes will increase their benefit and maximize their life span. Platinum pated titanium anodes provide a cost effective replacement for lead anodes in electro plating or hard chromium plating. They provide superior quality deposition and consistency resulting in increased productivity and throughput. Cost benefit analysis demonstrates that the higher initial investment in this technology can be recouped within a short period of time.

5ea4aac2-dc96-4e59-b029-23bc10640562|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

Posted in:

Tags: Platinized Sheet Anode, Platinized Flat Anode, Platinized Perforated Sheet Anode, Platinum Plated Anode, Water Ionization Anode, Alkaline Anode, Ionizer Anode, Ionization Titanium Anode, Platinised Sheet Anode, Platinum Coated Sheet Anode, Platinum Plated Sheet Anode, platinum activated Anode