Platinum Plating Titanium Anodes using high-temperature electrolysis offers two additional ecological benefits: Considerably longer life span based on better durability. Sparing use of platinum (which is made resistant to corrosion through high-temperature electrolysis). Re-platinization of the base substrate means that any existing platinum can be refurbished and reused, saving costs.

Gravure printing is widely used for printing magazines, catalogues, stamps, packaging, wallpapers or decorative papers for the furniture industry as well as elaborate artistic publications. The gravure cylinder used for this method consists of a steel core which is coated with copper. To increase the wear resistance, a chrome layer is subsequently applied. For both electroplating processes, given tolerances must be controlled to ensure print quality meets quality standards.

As an engraving material, copper is comparatively “soft”. To increase the hardness, additives are added to the electroplating bath. By nature, chromium is a hard metal with a fine grain structure. This makes it ideal for protecting the engraved copper deposits applied to gravure cylinders. During press runs of any length hard chromium protects the cylinder from wear caused by paper and grit abrasion and, under normal conditions, enables the cylinder to print in clearer, sharper lines for the entire run.

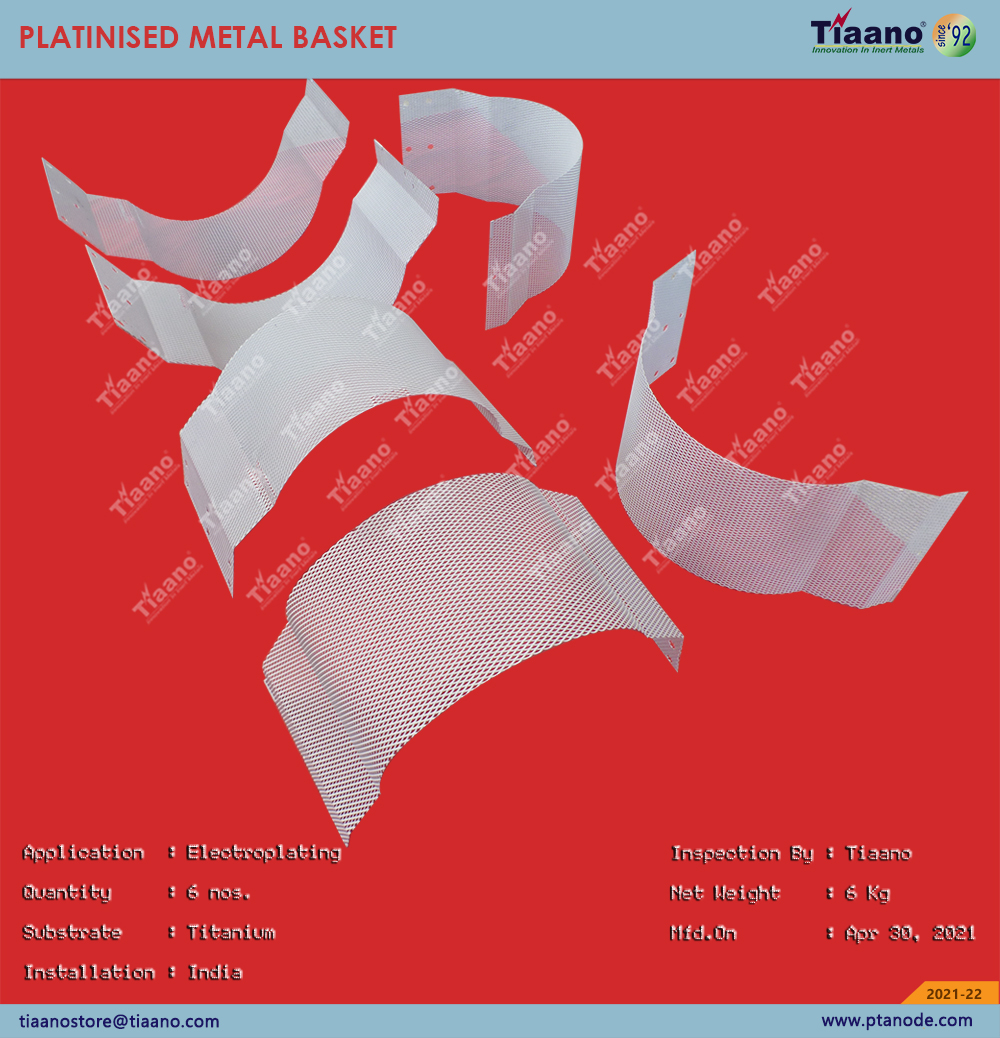

Advantages of Platinized Anodes in gravure / Rotogravure Cylinders Plating:-

Long life, dimensionally stable and easily fabricated into required shape

Homogeneous and long-lasting active surface

Energy savings with shaped anodes and small anode/cathode distances

Reduced environmental burden and reduced maintenance

Mesh anodes provide excellent throwing and can be used at high current densities

Easier handling and replating