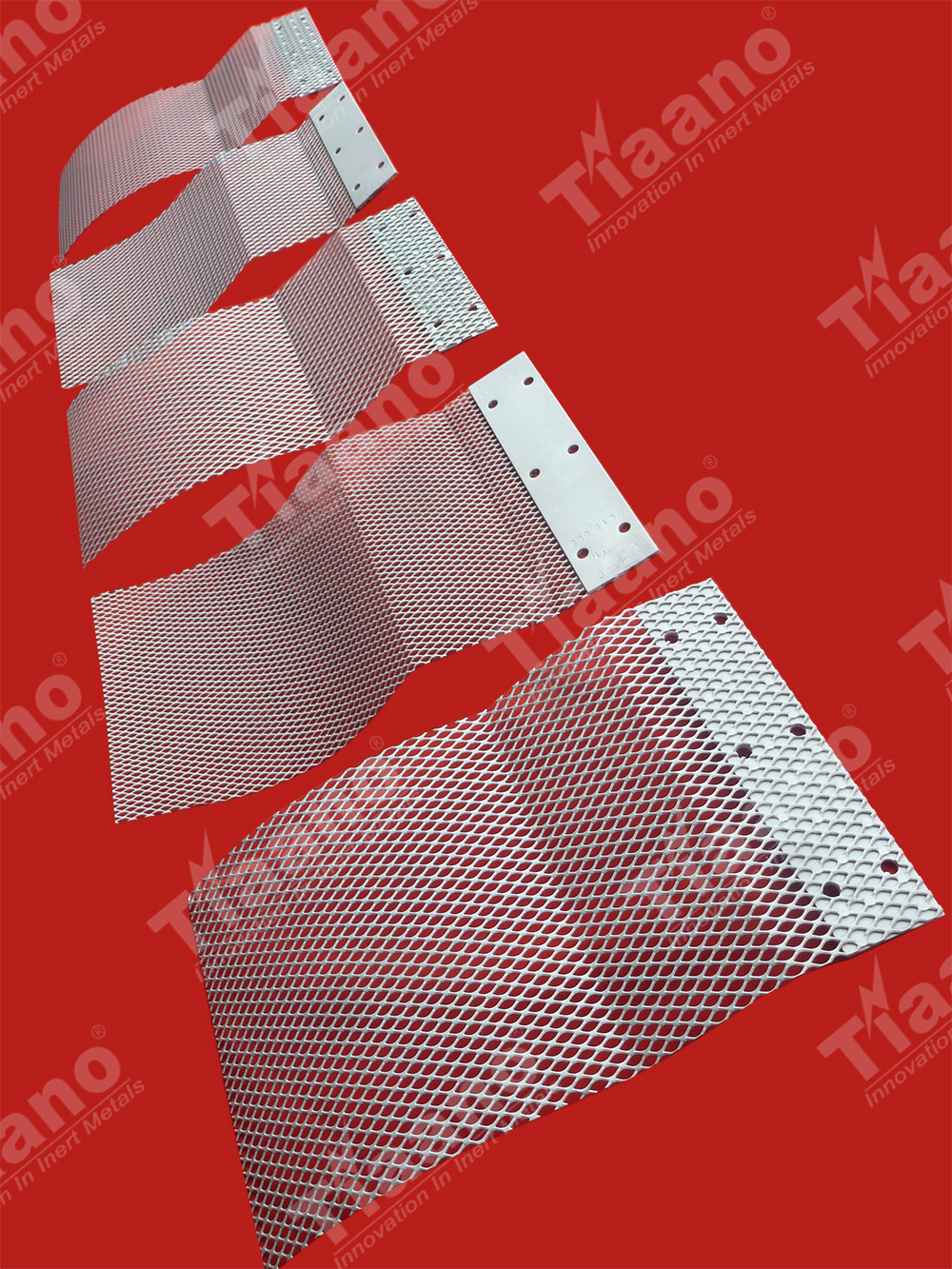

Platinised Titanium Expanded Mesh Anode for Hard Chrome Plating Industries

March 18, 2020 at 8:43 PM

—

Platinised

Platinum plated titanium anodes have been successfully used in hard-chrome plating. As long as suitable electrolytes are used, a completely lead-free process is usually possible without excessive costs by simply replacing lead anodes with Pt/Ti anodes. Plating anodes using high-temperature electrolysis offers two additional ecological benefits: Considerably longer life span based on better durability. Sparing use of platinum (which is made resistant to corrosion through high-temperature electrolysis). Re-platinization of the base substrate means that any existing platinum can be refurbished and reused, saving costs.

Another benefit of the Platinised anode is that they require no touching up due to the dimensional stability and the high-temperature electrolysis that allows up to 99.99% purity in platinum coatings, as well as excellent adhesion and ductility.

An investment of three to five times the annual costs for standard lead anodes in the first year, and a company can expect to break even within around three years of installation.