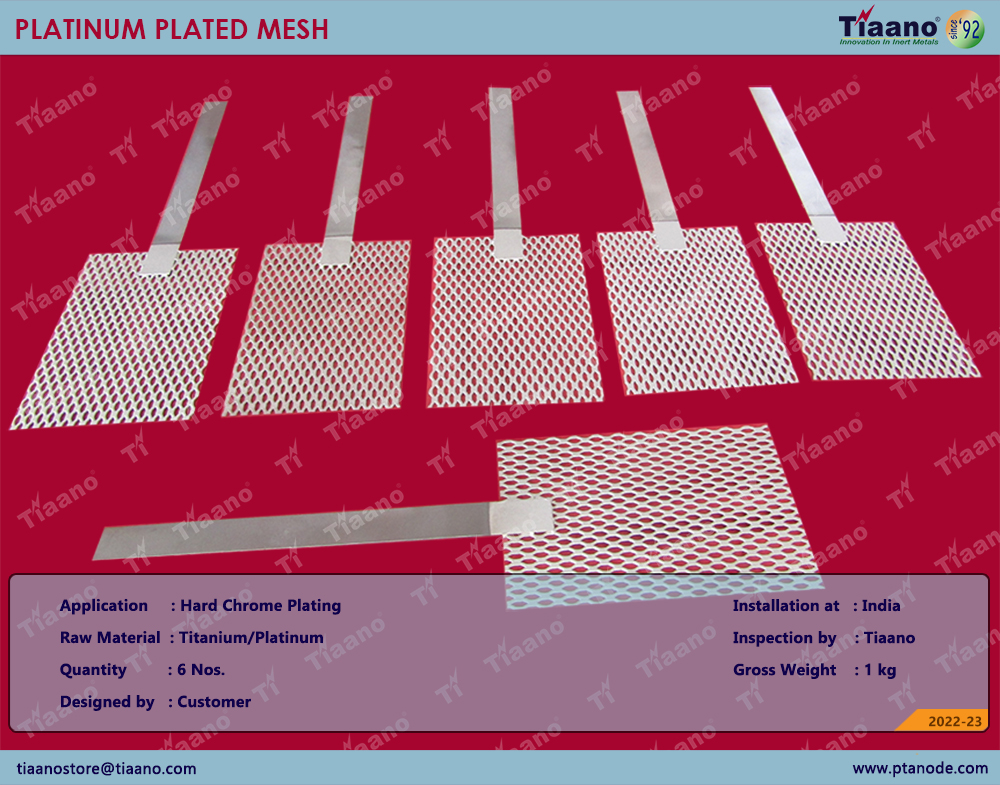

Platinum Plated Titanium Mesh Anode for Hard Chrome Plating Application

July 2, 2022 at 6:51 PM

—

Platinised

Tiaano Platinised Titanium Anode for Hard Chrome Plating. Current hard chromium plating processes are basically founded on chromic corrosive and sulfuric corrosive. The idea of chrome electroplating shower can affect the life span of the anodes. Specifically, free fluoride particles; it can go after the metals of the anode and cause erosion.

Lead tin combination anodes are ordinarily utilized for hard chrome plating. Be that as it may, the slop of lead chromate is typically framed on the lower part of the plating tank. As a delicate metal, lead compound anode is effectively distort or twist. It influences the ongoing thickness and result in lopsided plating thickness and may cause hamper.

Platinized titanium anode is a decent choice in hard chrome plating. It lessens how much perilous lead ooze age, is layered dependability, bringing about a more steady, homogeneous, and reliable thickness plating process. Platinized anodes are substantially more adaptable in forming and dimensioning and can be planned by the states of the work pieces to be plated.

For Plating, Tiaano has planned a high-temperature electrolysis strategy for platinum plating. The immaculateness of the plating is at 99.99 percent. The pliability, grip and consumption opposition of the platinum plating are impressively better, while the inner burdens are kept to a base. The plating or covering thickness appropriation is significantly more uniform, due to the layered dependability of the anodes.

Tiaano offers New Anodes, Anodes repair and Rectification and Replating or Recoating