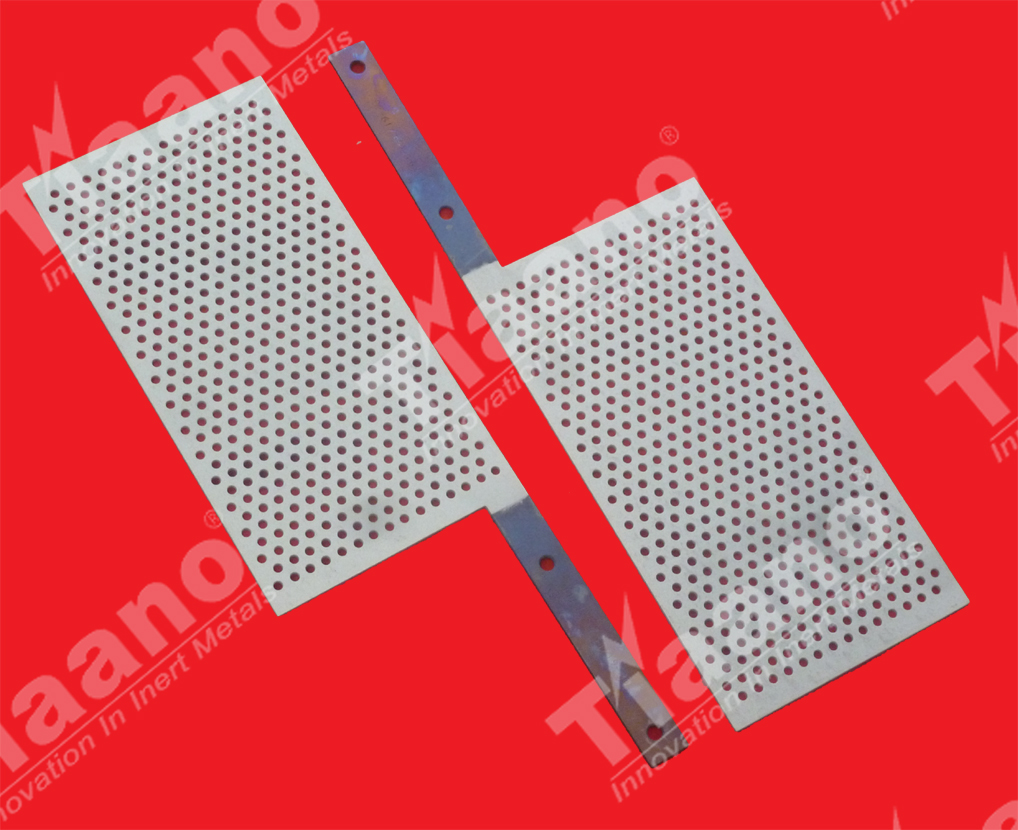

REPLATING OF MULTHOLE TITANIUM ANODE FOR ELECTRO PLATING - TIAANO MANUFACTURER AND SUPPLIER OF PLATINISED TITANIUM ANODES AND PLATINISED NIOBIUM ANODES

September 29, 2020 at 6:00 PM

—

Platinised

Electroplating is used in a variety of industries for coating or plating metal objects with a thin layer of a different metal. This electroplating process requires anodes or Electrodes. Especially platinized Titanium or Platinised Niobium anodes. The most common uses for electroplated products are chrome-plated oil pump auger flights, hydraulic cylinders, conveyor flights, sheets and tanks where it would be impractical or too expensive to make the item entirely out of the plating metal.

Platinised Anode describes the refractory metals. Refractory metals such as titanium, niobium, tantalum, molybdenum and tungsten are usually used as the substrate in the production of platinized Anodes. Expanded metals, sheet metals, round stock, tubes, rods, ribbons and wires of the most varied materials and dimensions are available. The base metals or Substrate meet the specifications of ASTM.

Field of Applications platinized Anodes (PT Anode / Pt Anode)

|

Field or Application

|

Platinum Requirements

|

|

Rhodium baths, Strongly Acid

|

1.5 Micron

|

|

Gold bath / Weakly Acid Bath

|

1.5 Micron

|

|

Gold bath / Alkaline

|

1.5 Micron

|

|

Hard Chrome plating

|

2.5 Micron / 5 Micron

|

|

Nickel / Nikel Alloy Bath

|

1.5 Micron

|

|

Cyanide Waste

|

1.5 Micron

|

|

Anodizing

|

1.5 Micron / 2.5 Micron

|

|

Hard Chrome Plating Fluoride Free

|

Platinised Titanium Anode (Pt Ti Anode)

|

|

Hard Chrome Plating Fluoride Containing

|

Platinised Niobium Anode (PT Nb Anode)

|