REPLATING OF TITANIUM ANODES AND REPLATING OF NIOBIUM ANODES FOR ELECTROLYSIS - TIAANO MANUFACTURER AND SUPPLIER OF PLATINISED TITANIUM ANODES AND PLATINISED NIOBIUM ANODES

September 27, 2020 at 11:31 PM

—

Platinised

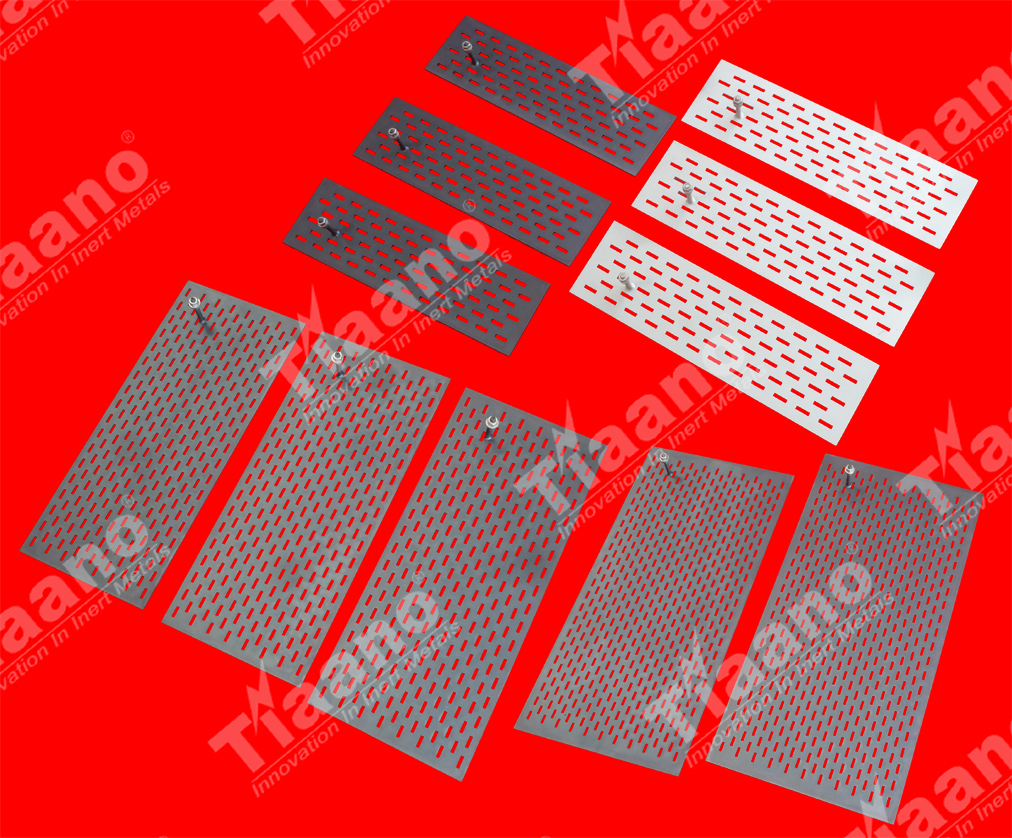

Tiaano, a complete design and manufacturing the Platinised Titanium / Platinised Niobium Anodes various electrolysis industrial applications. Tiaano manufacturing different sizes and Shapes of Platinized anodes in the form of either sheet, expanded mesh, rod, wire or tube and custom made. Re-plasticization also very much possible. Re-plasticization of the base substrate means that any existing platinum can be refurbished and reused.

Advantages of Platinized Anodes:-

Platinum has the advantages of electrochemical inertness, mechanical strength, workability and favorable electrical conductivity. However, it is prohibitively expensive. Development of Platinum on Titanium, Platinum on Niobium and Platinum on Tantalum (plated) materials has opened up the feasibility of using these for anode materials for Electro Plating, metal finishing and cathodic protection systems in critical applications.

Technical characteristics of Platinized Anodes: high current efficiency; excellent corrosion resistance; long electrode life; electrode shape can be designed according to user needs; electrode substrate can be reused several times; no pollution to the medium (electrolysis); can withstand higher Current density.

Specifications of Platinized Plated Anodes:-

|

Substrate Standard

|

Titanium As per ASTM

|

Niobium As per ASTM

|

|

Substrate Purity

|

99.9% pure

|

99.9% pure

|

|

Anode Shape

|

Titanium Sheet, Wire, Rod, Expanded Mesh, Tube

|

Niobium Sheet, Wire, Rod, Expanded Mesh, Tube

|

|

Plating (Catalyst)

|

Pure Platinum

|

|

Purity of Platinum Catalyst

|

100%

|

|

Platinum Thickness

|

0.5 to 20 Micron

|

|

Plating Process

|

Electro deposition

|

|

Catalyst Color

|

Silver White

|