The leading anti-corrosion character, outstanding physical & mechanical properties, uniform current distribution characters of titanium, niobium - its Platinised anodes and Mixed Metal Oxide coated anodes are strongly recommended for Impressed Current Cathodic Protection (ICCP) application.

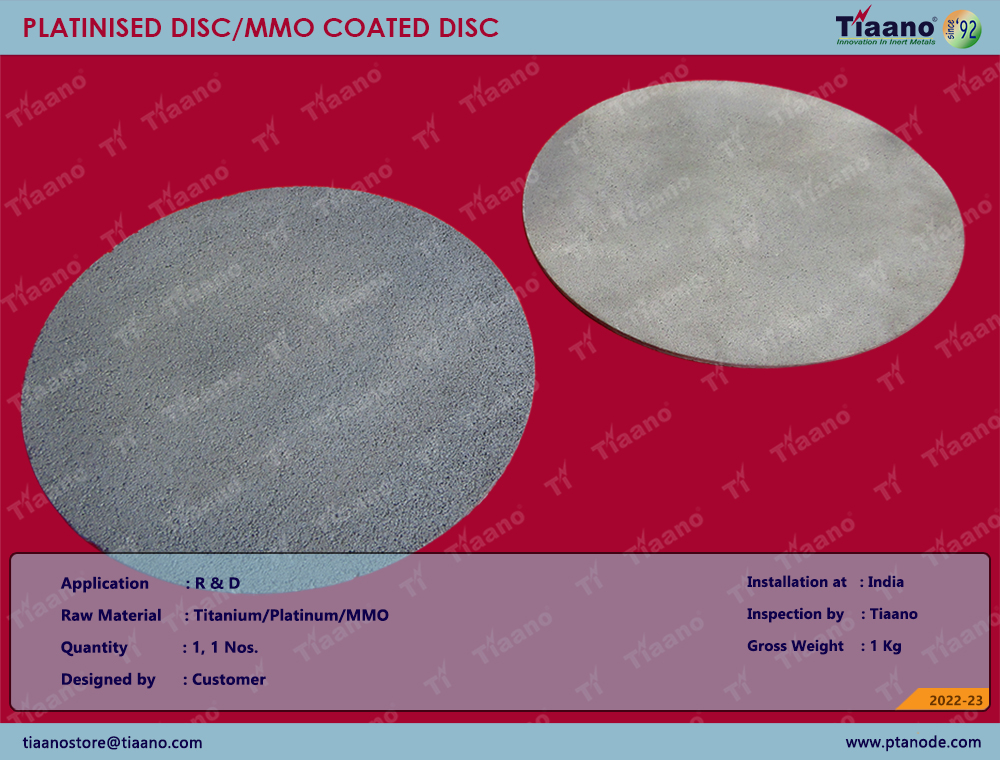

Application Of MMO / Platinised Disc :

Curved and Strip Anodes are grown explicitly for insurance of Dam and Navigation lock entryways.

Curved and strip anodes are intended to work in new, salty and seawater conditions - utilized in other appropriate applications.

Incorporates marine designs, water tanks and vessels. With a discretionary essential seal spacer gasket.

FABRICATION OF ELECTRODES USING PLATINUM:

Platinum is one of the most commonly used materials for implantable electrodes and there are a number of processing techniques that can be applied for dense, microfabricated arrays. In the following sections some of these techniques have been described.

ELECTRODEPOSTITION OF THICK PLATINUM STRUCTURES TO FORM IMPLANTABLE ELECTRODES:

The deposition of the platinum electrode is important in the overall performance of the electrode array. The material has to be deposited to the required thickness and provide a good bond to the substrate.

There are two techniques commonly used to deposit thick film platinum:

1. Electrodeposition (or electroplating) and sputtering. The former is suitable for producing thick films, whereas the latter is only suitable for thin films.

2. In the case of implantable electrode arrays, there is a need to minimise the impedance of the electrodes, so thick films are preferred.