Ti Anode Fabricators Pvt. Ltd, we offer Platinum plated titanium anode, Negative plate – cathode, triple oxide coated anode, MMO coated anode, Platinised titanium anode, Platinum coated niobium anode and Platinum coated titanium anode from India.

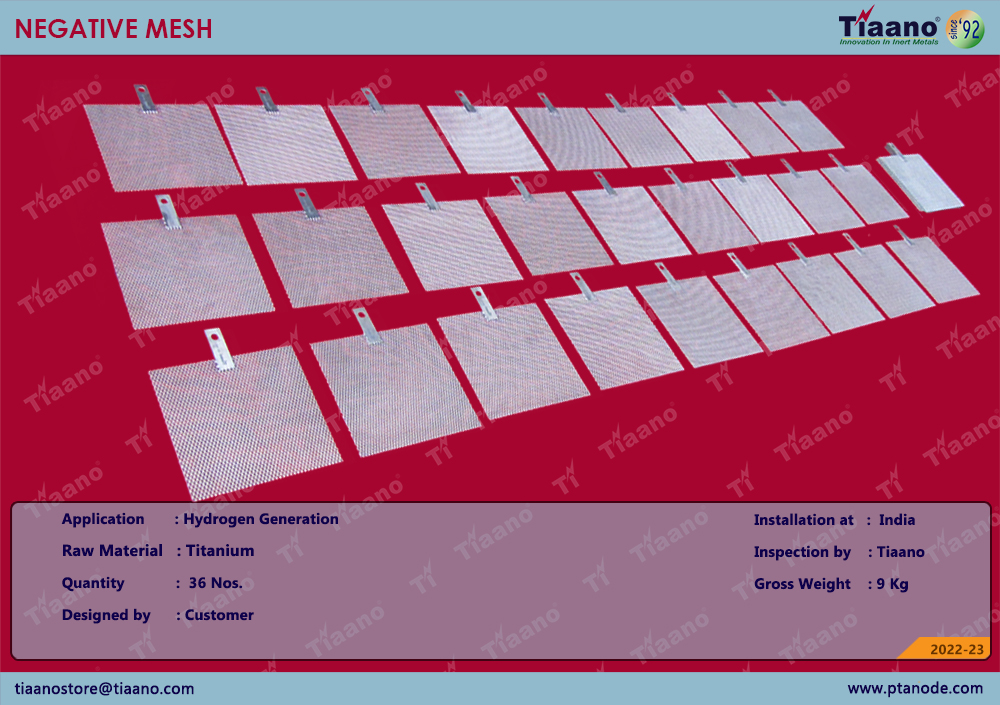

NEGATIVE MESH (CATHODE):-

The Titanium Negative Plate and Sheet is mostly used, because it has outstanding practical performance, such as strong ability of ionization release, good exchange of electrolyte, close structure and light weight, etc.

Substrate: Pure Titanium

Grade: TI GR. 1

Substrate Shape: Mesh, Plate, Sheet, Tube, Rod , Wire or Customized.

Thickness of Negative Plate: 1 MM THK

Scope of Application: Ionization.

Ti Anode Fabricators Pvt. Ltd, we offer Platinum plated titanium anode, Negative plate – cathode, triple oxide coated anode, Mmo coated anode, Platinised titanium anode, Platinum coated niobium anode and Platinum coated titanium anode from India.

PRODUCT FEATURES:

1. Water ionization, Water treatment devices & Chlorate manufacturing.

2. Long working life, Light weight

3. High current density

4. Stable operating voltage

5. Electrolysis processing, Electroplating, Chemical processing & Medical Industries.

6. The service life of the negative plate titanium cathode depends on the working medium (electrolyte) and the current intensity of the anode (current density).