A platinized titanium anode is simply a titanium anode plated with pure platinum or platinum metal oxides. Platinized titanium anodes act as inert anodes and are non-consumable and long lasting. Platinised titanium anodes are very frequently used as expanded metal mesh anodes due to their excellent practice characteristics.

Advantages of Platinum Plated Expanded Mesh Anode:-

Long operating life and maintenance-free.

Economical and low platinum requirements

High dimensional stability and load resistance.

Good current distribution.

High corrosion resistance.

Light weight and Easy installation

Some applications where these anodes are used:-

Electrosynthesis and Electrodialysis

Chlorate and perchlorate production

Eectro-chlorination

Electroplating and Electro painting

Cathodic Protection (ICCP)

Water Treatment, Waster Water and Sewage treatment plants

Anode – Material of Construction:-

Platinized Titanium anode (Pt-Ti): Platinum plated over Titanium

metal (Titanium Metal substrate) anode.

Platinized Niobium anode (Pt-Nb): Platinum plated over Niobium

metal (Niobium Metal substrate) anode.

Platinized Tantalum anode (Pt-Tl): Platinum plated over Tantalum

metal (Tantalum Metal substrate) anode.

Platinized zirconium anode (Pt-Zr): Platinum plated over Zirconium

metal (zirconium Metal substrate) anode.

Platinum plated tantalum / Zirconium anodes are available for special applications.

We supply comprehensive range of anodes in geometries, bar, rod, spaghetti, cylinder, wire, grid/ mesh, round, square and custom to complement wide range of electro-chemical processes.

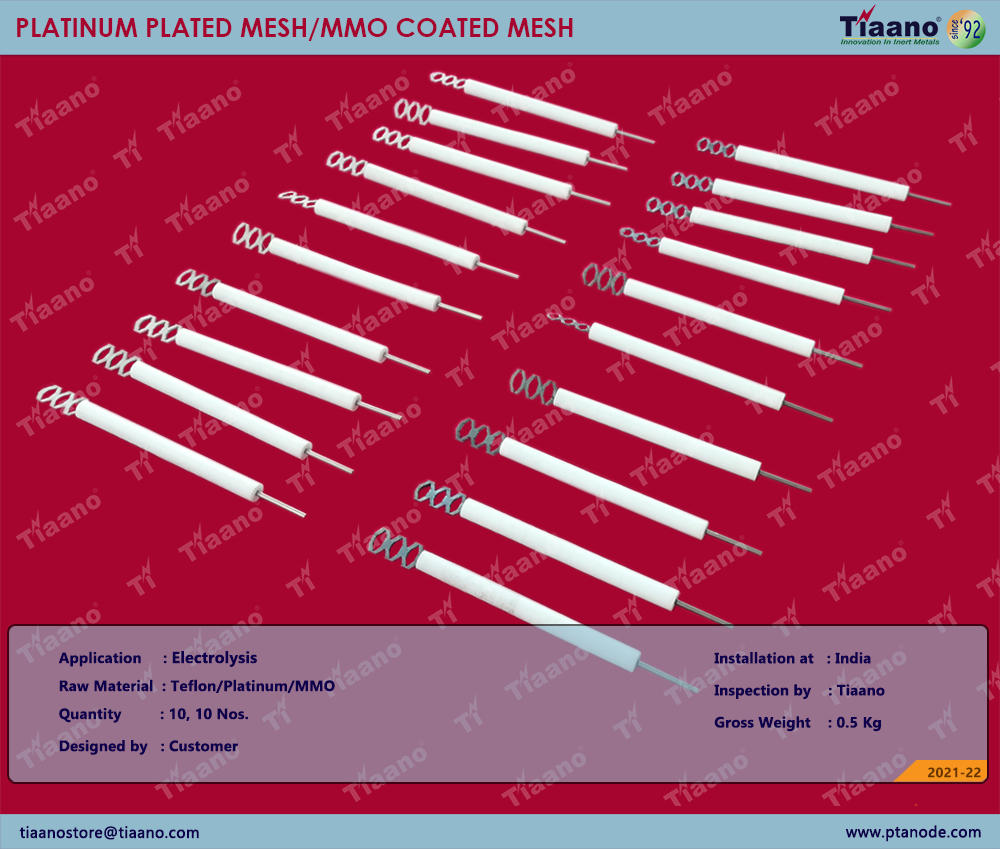

Details of Platinum Plated Titanium Mesh Anode:-

Tiaano: Manufacturer and Supplier of Platinum Plated Titanium Mesh Anode.

Anode: Expanded Mesh

Application: Electrolysis, Electro Chemical Production

Year of Established: 1992.

Installation at: Varanasi, India.

Inspection by: Tiaano.

You may refer more details from here:-

Facebook Page, Instagram Page, Twitter Page, Pinterest Page

Platinized Titanium & Niobium Anode (Dimensionally Stable Anode)