Platinized Anodes (Pt. Anode) are produced by plating platinum (Pt.) on a specially treated precious metal (Titanium / Niobium / Tantalum) substrate by means of electrodeposition process. They are economical as well as it retains the superior physical and chemical properties of platinum. It is the most effective metal for any electrolysis process due to its current conducting property.

Uses of electrolysis:

Electrolysis is used extensively in metallurgical processes, such as in extraction (electrowinning) or purification (electrorefining) of metals from ores or compounds and in deposition of metals from solution (electroplating).

Electrolysis is used in the extraction of metals from their ores. For example, when a current is passed through molten sodium chloride, sodium is deposited at the cathode and chlorine gas is evolved at the anode. Aluminium and potassium are also extracted by electrolysis.

It is used for refining certain metals such as copper and zinc.

Electrolysis is used for the manufacture of chlorine. In submarines, oxygen produced by the electrolysis of water is used for breathing.

Electrolysis is used for electroplating many things we use every day.

Important parameters determining the anode design are:

The electrochemical cell or installation wherein the anodes are used

The process conditions, such as electrolyte composition, temperature, current density, design life, etc.

Mechanical load of the anode

Capacity of electrical conductivity of the base material.

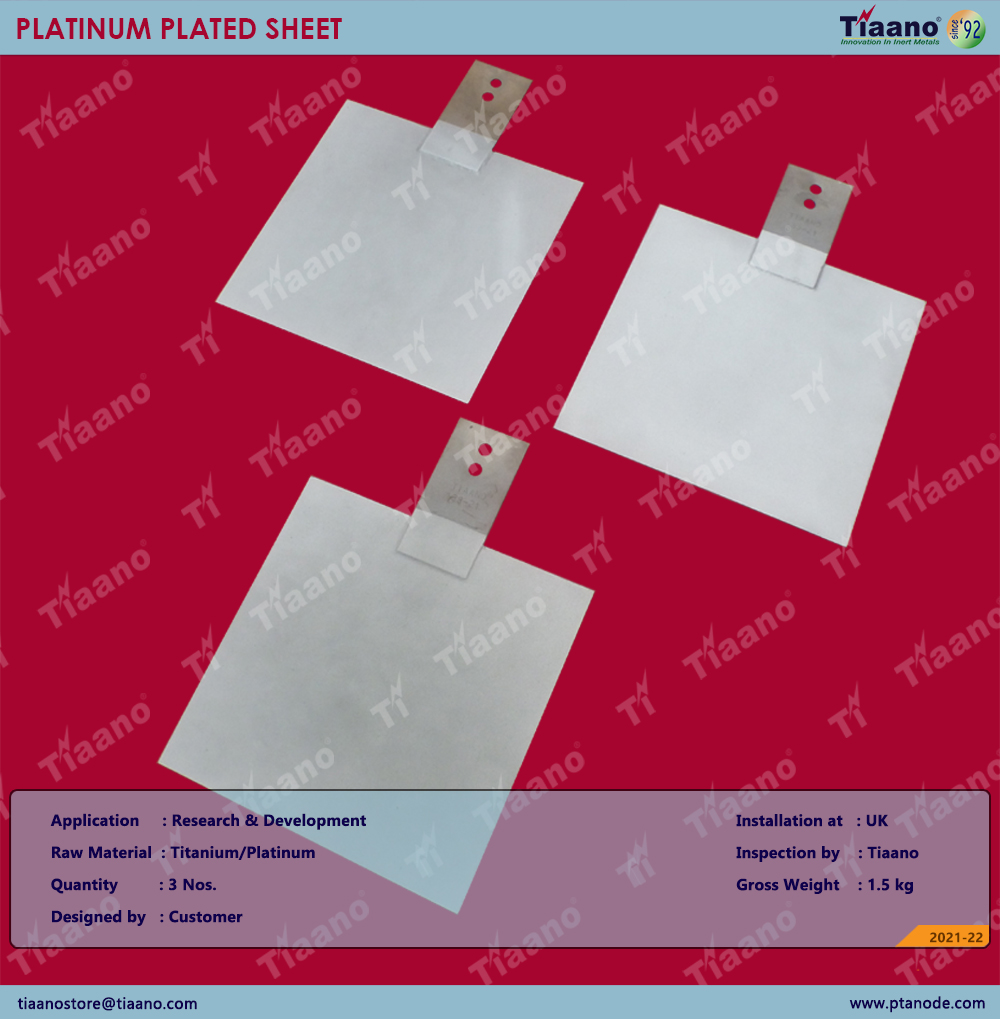

Because of a very flexible production facility, we are able to manufacture anodes of all types. Sheet, plate, mesh, wire, rod, tubular or combinations and/or assemblies of these materials. Their size and number vary from several cm2 to 2 m2 and quantity 1 to 10,000 numbers. All anodes are produced according to customer specifications.

Anode Types:-

Box anode, Rod anode, Wire anode, Ring anode, Plate anode, Ribbon anodes, Tubular anodes, Strip anodes, Mesh anodes, and any other geometry

• Product: Titanium with platinum Anode / Electrode

• Use: Noble metal plating (silver, gold) Sea water antifouling, Electro Chemical Process

• Coating / Plating: pure platinum Plated / Coated / Activated / Deposited