Tiaano Platinised Titanium or Platinised Niobium Anodes are most suitable for electro plating of precious metals like gold, platinum, palladium, chromium, nickel, rhodium and copper etc…

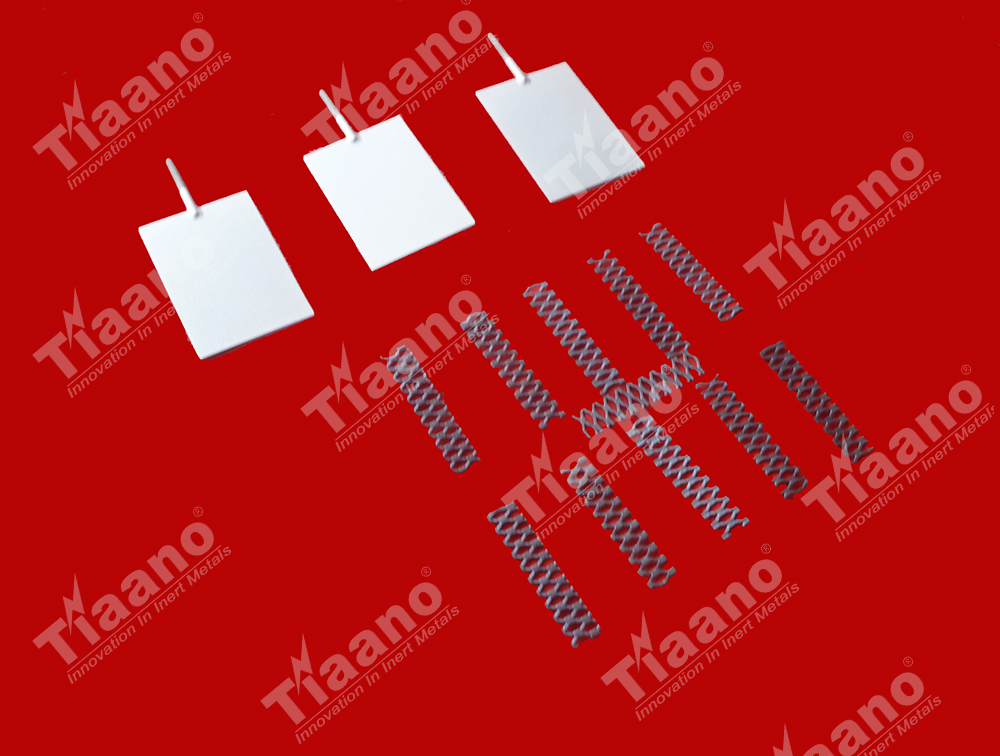

Platinised anodes consist of a titanium base or Niobium base, in the form of either expanded mesh, sheet, rod, wire or tube with a plating of platinum between 2 to 5 microns thick and purity of platinum is 99.99%. They possess the electrochemical properties of platinum. The titanium used is 99.9% pure as established by ASTM (American Society of Metal).

The service time of the platinised titanium anodes depends on the chemical resistivity of the base metal, the dissolution rate of the deposited platinum in the electrolyte, which in turn depends upon layer morphology, and adhesive qualities, pH, current density and current ripple. For most applications the dissolution rate is low and the advantages of platinized titanium anodes are far greater than any metal loss.

Advantages of platinised Titanium Anode:-

• Long operating life, maintenance-free.

• Economical due to low platinum requirements.

• High dimensional stability and load resistance.

• Good current distribution.

• High corrosion resistance.

• Low weight.

Properties of platinum Plating: -

Softness, Good adhesion, High plasticity, High ductility, High Purity.

Tiaano also supply Titanium, Niobium, Hastelloy, Zirconium and Nickel equipments for Electro Plating Industries, such as….

1. Jigs & Fixtures

2. Racks

3. Anode Baskets

4. Tanks

5. Heating Cooling Coils

6. Chillers

7. On site welding service