Tiaano provides Platinum plating on Titanium in the form of sheet, expanded mesh, pipe, wire, rod and custom built as Anodes and cathodes (Electrodes) for various industrial electrolysis applications, Including Electro Plating, Electrolytic Recovery, Electro – Chemical Sensing, Electro Winning refining of metals, Electro Galvanizing, , Regeneration of Chromic Acid, Electro – dialysis, Cathodic Protection, Electrolytic production of Sodium hydro Chlorate.

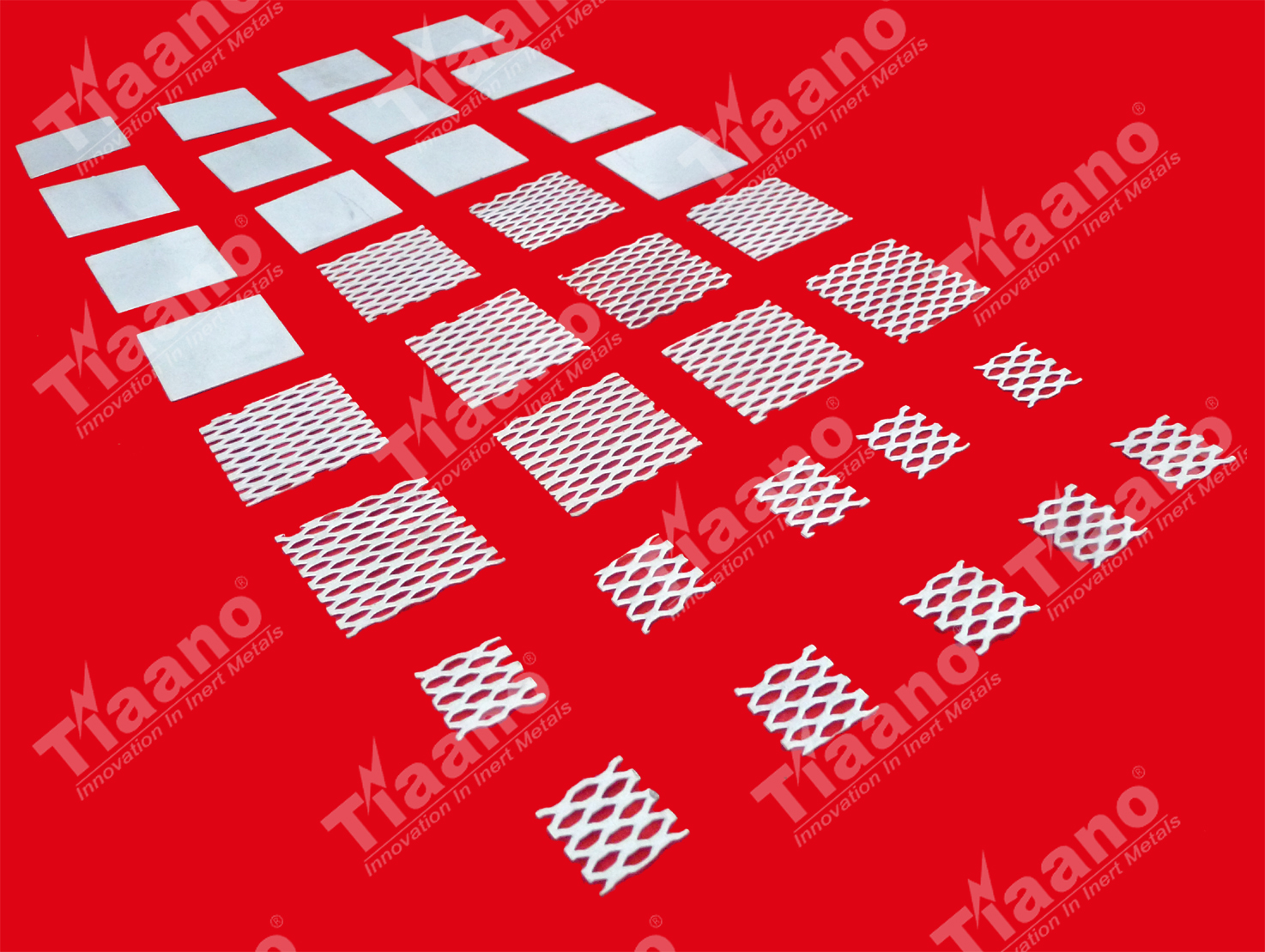

Type of Platinised Titanium Anodes or Electrode we offer:-

Ø Platinized Titanium Rod Anode

Ø Platinised Titanium Wire Anode

Ø Platinised Titanium Sheet / Plate Anode

Ø Platinised Titanium Expanded Mesh Anode

Ø Platinised Titanium Perforated anode

Ø Platinised Titanium Basket anodes

Ø Platinised Titanium Tube Anode

Ø Platinised Titanium Disc anodes

Ø Platinised Titanium Strip anodes

Ø Platinised Titanium Slotted anodes etc…

According to the substrate material used, the platinized anodes are classified as

1. Platinized Titanium anodes

2. Platinized Niobium anodes

3. Platinised zirconium anodes

4. Platinised Tantalum anodes