Long life, dimensionally stable and easily fabricated into any shape: When used in the plating process, dimension of the lead anodes are changing due to the loss of the lead oxide which is formed on the anode during operation - it leads surface area is getting collapsed . Also larger lead anodes can lengthen under their own weight. Whereas titanium anodes are dimensionally stable throughout their operating life and can easily be manufactured, even in complex shapes and lengths, up to 4m. Consequently, shaped anodes can be manufactured very accurately to allow consistent plating to small tolerances, often making a further honing step unnecessary.

Homogeneous and long-lasting active surface: When lead anodes are not in use the lead oxide layers change to lead sulphate and lead chromate, which are not good conductors and consequently do not perform consistently. Platinised titanium anodes operated correctly, remain deposit free and therefore perform constantly well throughout the whole anode life.

Energy savings with shaped anodes and small anode/cathode distances: Small electrode gaps reduce electrical resistance losses in the plating bath and produce energy savings. In the case of lead anodes, which cannot be formed as accurately as a mesh, resistance losses result in bath heating, requiring further energy for cooling. Therefore, platinised titanium anodes can provide energy savings both in heating and cooling which, in turn, allows the plating chemistry to be easier to manage and maintain.

Reduced environmental burden and reduced maintenance: No chemical cleaning or brushing of passivated areas is necessary. Bath life is increased as there is no formation of lead sludge - lead anodes produce about 3g of lead sludge for every 1kg of chromium deposited in sulphuric acid type baths and even higher in other baths. Furthermore, the reduced resistance losses and subsequent need for cooling allow for easier maintenance and control of the plating chemistry.

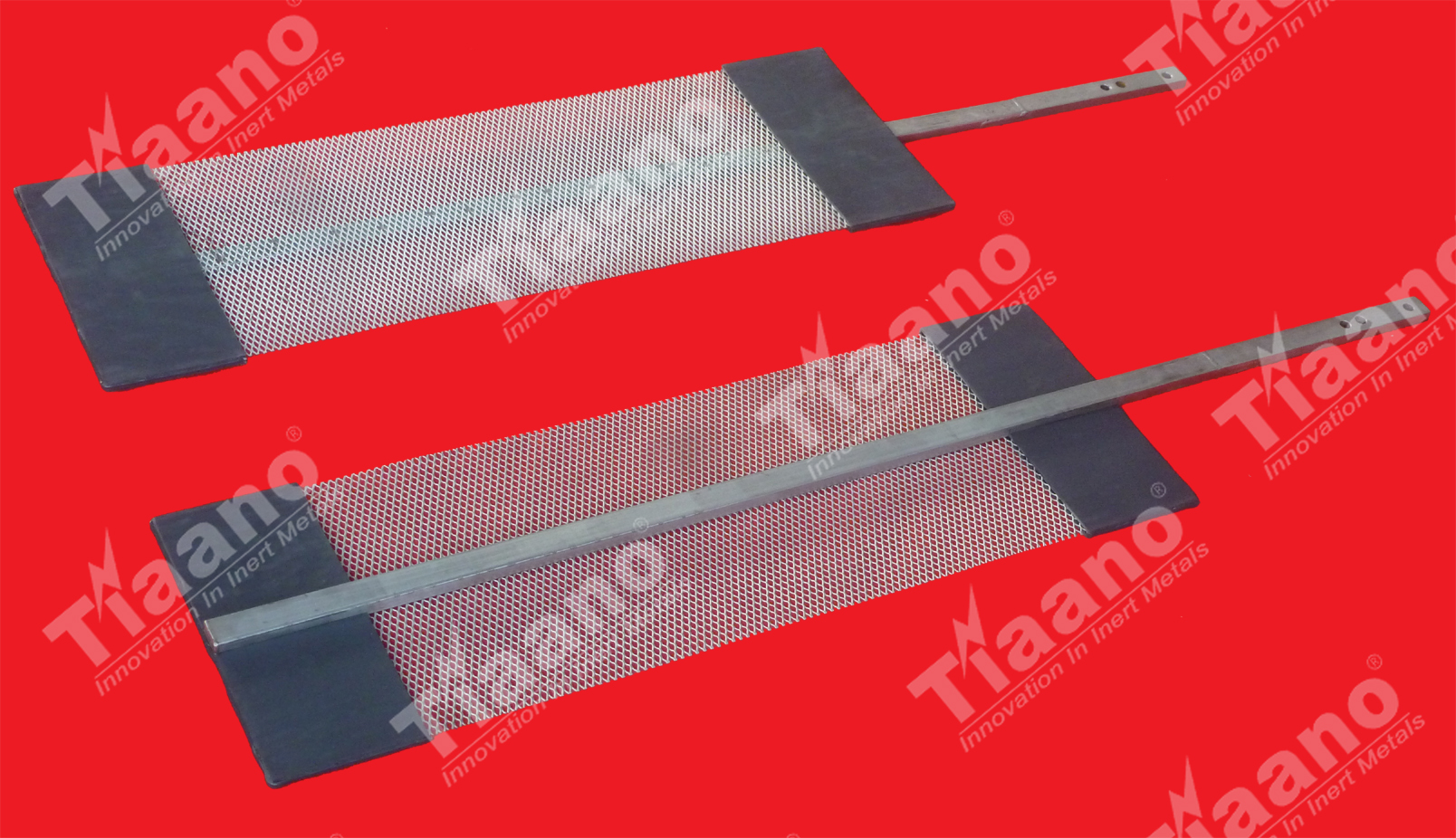

Mesh anodes provide excellent throwing and can be used at high current densities: In electrolysis, corners and edges are preferred reaction sites; an expanded mesh has edges evenly distributed across the anode surface, thus producing uniform current density and excellent plating results. Large area mesh anodes improve throwing power and the mesh structure allows good solution movement and electrolyte exchange and plating with high current densities.

Easier handling and recoating: Positioning of lead anodes for optimising chrome plating is often awkward due to their weight, whereas spot welded or bolted mesh anodes are very light by comparison and allow safer and easier handling. Furthermore, they can be easily removed and / or replaced whenever necessary. This often allows a re-use of expensive anode materials and designs, and reduces operational costs.

Considerations when converting from Lead to Platinised Titanium anodes:

Where platinised titanium anodes are used as a replacement for lead anodes consideration must be given to several factors to ensure that the technology is utilised to its full potential – a change in plating process is necessary and, as such, the whole plating set-up and its costs need to be considered to maximise the return on the investment in these anodes.

Consideration should be given to:-

Thorough cleaning of the plating tank and associated equipment with an adjustment of the residual lead concentration.

Bath/Electrolyte composition and operating conditions.

Current Density and operating Voltage.

Anode design.

The service life of platinised titanium depends on both the electrolyte matrix and the applied current density. Therefore, in fluoride containing baths and at current densities >75 A/dm2 platinised niobium is recommended in preference to platinised titanium.

Platinised titanium and niobium anodes are completely or partially covered with a fee microns of platinum (usually 2.5µm). Where the platinum is consumed after years of use, the underlying titanium or niobium passivates and the bath voltage rises at constant current operation. The base metals are not attacked at the usual operational voltages, in fluoride free chromium baths.

For most applications the platinum wear rate is very low and the corresponding anode life time high. In sulphuric acid chromium baths the platinum consumption is between 1g and 4g platinum per million amp hours. Careful design of the platinised anodes will increase their benefit and maximise their life span.

Summary: Platinised titanium anodes provide a cost effective replacement for lead anodes in hard chromium plating. They provide superior quality deposition and consistency resulting in increased productivity and throughput. Cost benefit analysis demonstrates that the higher initial investment in this technology can be recouped within a short period of time.