Platinized titanium anode is a layer of platinum on titanium substrate. It is lasting, non-consumable and insoluble in the electrolyte, it is widely used in electroforming, electroplating and hard chrome plating field.

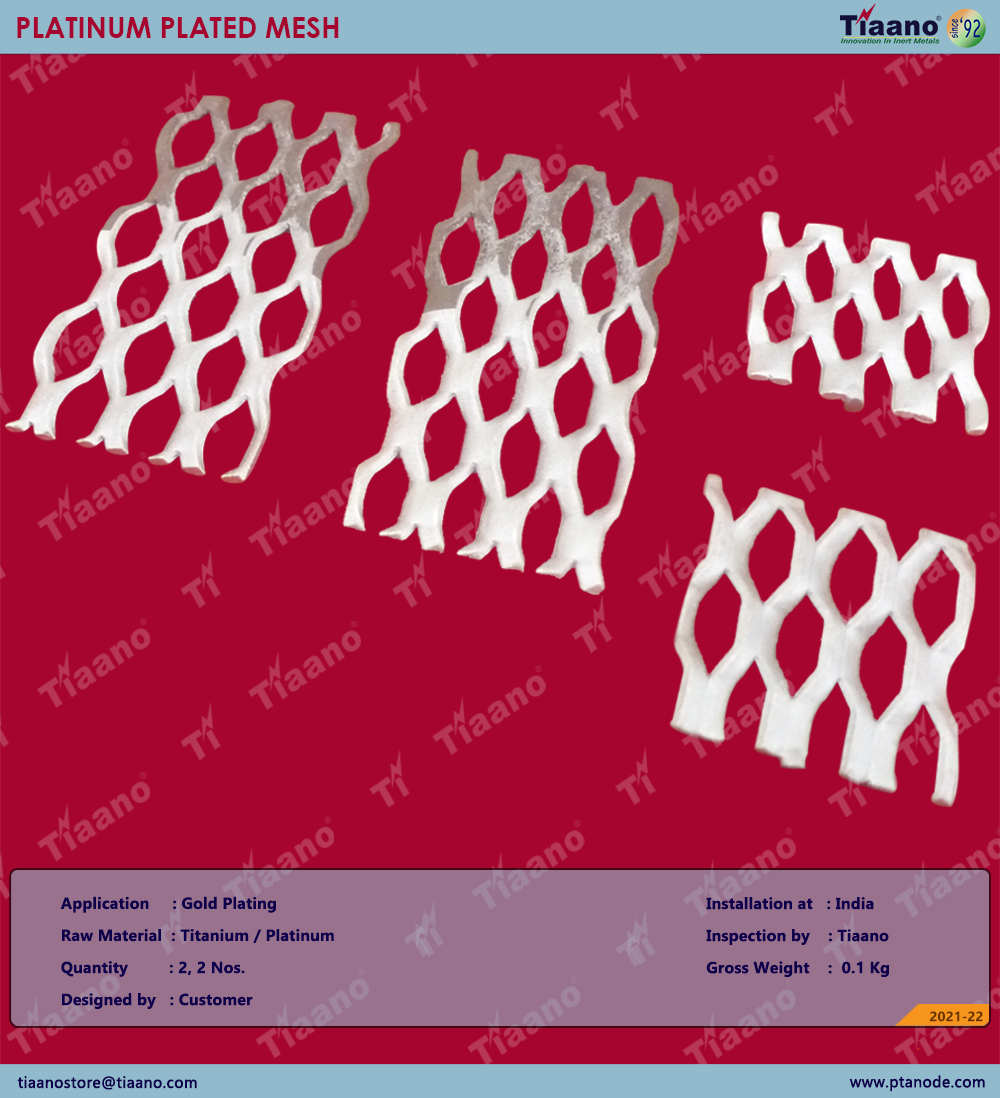

Tiaano manufactures platinized titanium anode by adopting Electro deposition process to get a dense wear-resistant layer of platinum coating. The anode surface is changed to improve adhesion of platinum and to significantly improve uniformity of coating or plating thickness. Also reduce the plating porosity imparting greater acid resistance to the anode. This platinum plated titanium anode can be fabricated into Plate, rod, sheet, mesh and other customized shape to meet the special needs.

Platinum Titanium Anode:-

Base material: Titanium Grade one

Plating material: Pure platinum

Technology: Electroplating or Electro Deposition

Size: Customization / Standard

Shape: Rod, Mesh, Wire, Tube, Sheet, plate etc

Features of Platinized Anode in Electro Plating or Electroforming:-

Anode Dimension remains constant over time

Energy savings

High corrosion resistance

High dimensional stability and load resistance

High levels of adhesion of the precious metal coating

Improved resistance to acid attack

Increased throughput with reduced plating times

Light weight (especially the mesh anode)

Long operating life; maintenance-free

Long service life under higher current density in acidic solutions

Produce complex shape of anode

General Application of Platinized Anode:-

Precious metal electroplating - Au, Pt, Pd, Rh and Ru baths

Non-ferrous metal electroplating - Ni, Cu, Sn, Zn and non-fluoride Cr baths

Printed circuit boards electroplating / Semiconductor

Impressed Current Cathodic Protection (ICCP)

Water Ionization / Water Ionizer

Electrolytic Chemical Production

Biomedical application

Projects for Reference:-

Platinized Titanium Mesh Anode for Gold Plating

Platinised Titanium Tube Anode for Hard Chrome Plating

Platinzed Titanium Anode for Electro Plating