Platinised Rod titanium and niobium Rod anodes are completely or partially covered with a fee microns of platinum (usually 2.5µm). Where the platinum is consumed after years of use, the underlying titanium or niobium passivates and the bath voltage rises at constant current operation. The base metals are not attacked at the usual operational voltages, in fluoride free chromium baths.

For most applications the platinum wear rate is very low and the corresponding anode life time high. In sulphuric acid chromium baths the platinum consumption is between 1g and 4g platinum per million amp hours. Careful design of the platinised anodes will increase their benefit and maximise their life span.

Platinised titanium anodes combine the excellent electrochemical characteristics of platinum with the good corrosion qualities of titanium. This anode is designed for Electro Plating application. They are characterised by the following features and advantages.

• Energy saving potential

• Low weight (in particular expanded metal anodes)

• Long service time even at high current density

• Dimensional stability, long durability of base material

• Replating possible

• Higher quality of end product

• Application-specific design

Type of Platinised Titanium Anodes or Electrode we offer:-

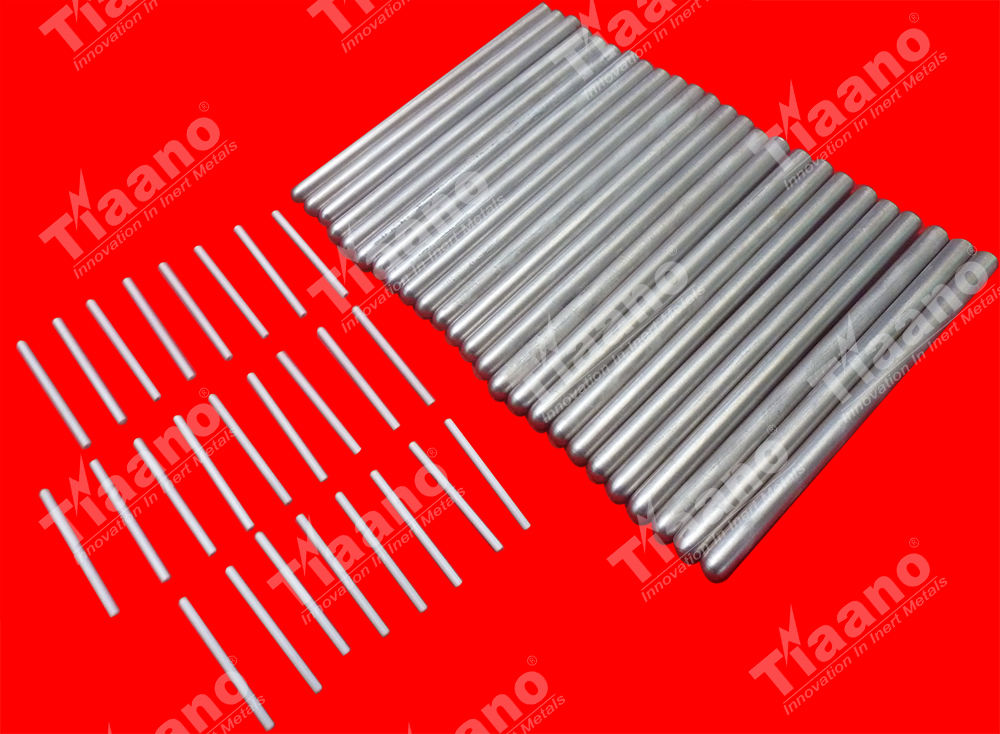

Ø Platinized Titanium Rod Anode

Ø Platinised Titanium Wire Anode

Ø Platinised Titanium Sheet / Plate Anode

Ø Platinised Titanium Expanded Mesh Anode

Ø Platinised Titanium Perforated anode

Ø Platinised Titanium Basket anodes

Ø Platinised Titanium Tube Anode

Ø Platinised Titanium Disc anodes

Ø Platinised Titanium Strip anodes

Ø Platinised Titanium Slotted anodes etc…

According to the substrate material used, the platinized anodes are classified as

1. Platinized Titanium anodes

2. Platinized Niobium anodes

3. Platinised zirconium anodes

4. Platinised Tantalum anodes

Specifications of Platinized Titanium Anode:-

|

Substrate

|

Titanium 99.9% pure As per ASTM Standard

|

|

Anode Shape

|

Titanium Sheet, Wire, Rod, Expanded Mesh, Tube

|

|

Plating (Catalyst)

|

Pure Platinum

|

|

Purity of Platinum Catalyst

|

100%

|

|

Platinum Thickness

|

1.5 to 20 Micron

|

|

Plating Process

|

Electro deposition

|

|

Catalyst Color

|

Silver White

|