The platinum plated niobium is plated or coated with platinum, which is especially suitable for high-speed and high current density electroplating baths. The niobium has excellent chemical resistance and electrical conductivity. The current that can be carried by a single area is titanium 4 to 5 times, so it is the best choice for high plating of precious metals. The service life is 4-5 times that of platinum titanium, and the bearing current is 4-5 times that of titanium, so the comprehensive performance can save 2.5 times the cost compared with platinum titanium.

Industries used: wheel plating, piston plating, precious metal plating, Automobile parts plating, Copper plating, Hard chrome plating, Rotogravure cylinder plating, Metal recovery, Refining, Chromium plating, Wire plating, Gold plating, Nickel plating, perchlorate, Bromate, Sodium chlorate, potassium chlorate etc…

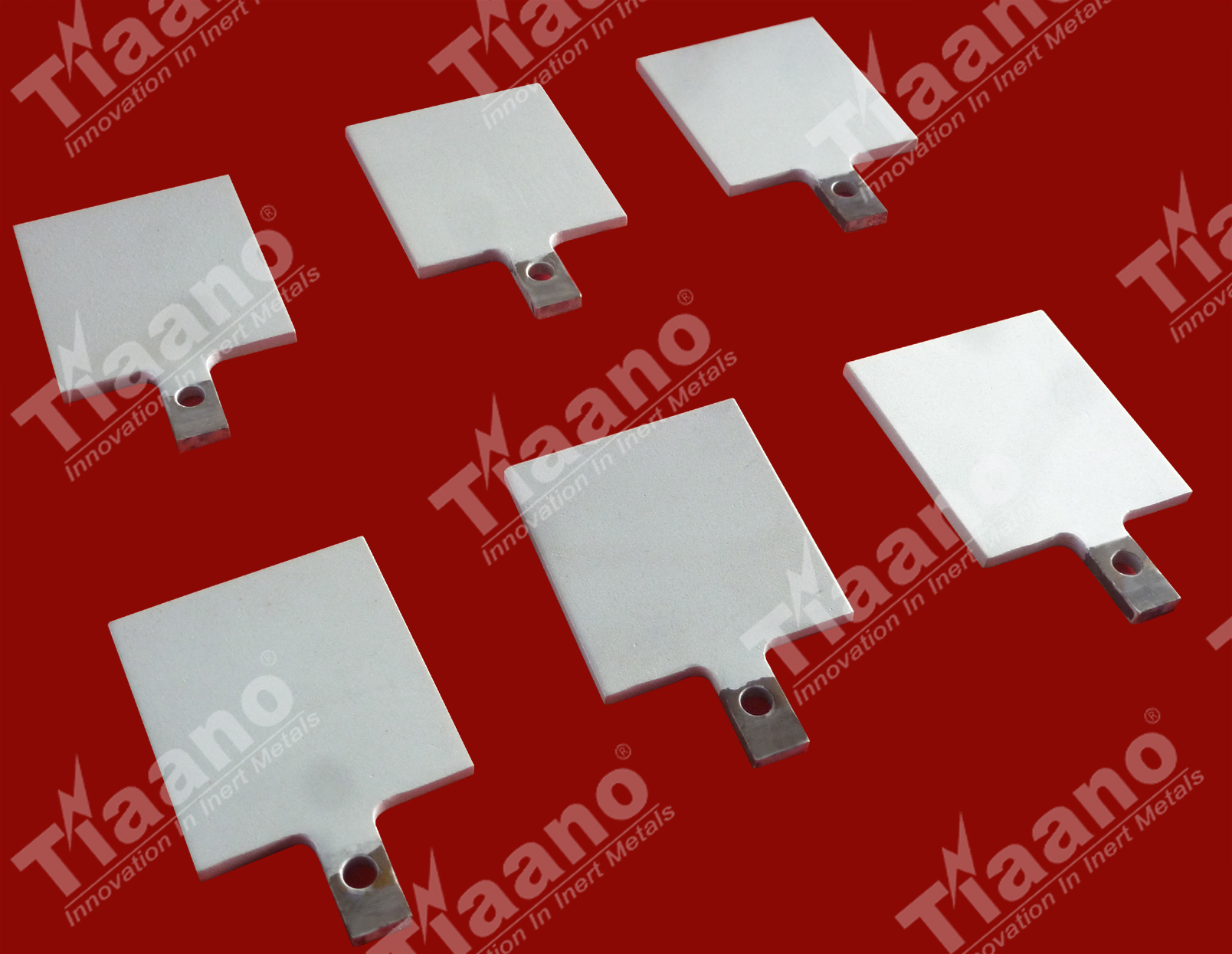

Advantages of Platinised Niobium Anode:-

1. Fabricate anodes with various shapes

2. Easy to operate, no maintenance required

3. Extremely high corrosion resistance

4. Suitable for fluorine-containing electrolyte

5. Operate higher current density

6. Longer service life.

7. Replating also possible

The anodes based on niobium metals are mesh, sheet, plate, rod, wire and tube. The thickness of standard platinum layer is 2-5micron for Electro Plating (2 to 10 micron for Heavy hard Chrome Plating). Breakdown voltage; especially in the use of electrolytes containing a small amount of fluorine, its long life and current density can reach 100A / dm2.

Technical Parameters for Platinum plated Niobium Anode:-

Base Material / Substrate: Niobium as per ASTM Standard (B 392 Gr.R04210, B 394 Gr.R04210 etc…)

Base Material / Substrate Shape: Expanded mesh, Sheet, Flat, plate (Peroration, slotted), Seamless tube, rod and wire

Platinum Thickness / Catalyst: 2 to 20 micron

Plating Method: Electro Deposition Process

pH Level: 1.0 – 10

Maximum Allowable Current Density: upto 100A / dm2

Maximum allowable Operating: 40 Volt