Tiaano is an approved manufacturer and supplier of Platinum Plated Titanium Anode for Various Applications. We are located in Chennai, India. Platinum coated (Platinised) Titanium Anodes are highly conductive anodes used in gold plating. Platinized titanium metal anodes are most suitable for wet electro deposition of precious metals like gold, platinum and chromium etc.

Benefits of Platinised Anodes in Gold Plating Process:-

Tiaano platinized titanium metal anodes are most suitable for wet electro deposition of precious metals like gold, platinum, palladium, chromium, nickel and copper etc. More over platinum is having very good physical and chemical properties such as …

Platinized Titanium Anode è Reduced plating times, High corrosion resistance

Platinised Titanium è Good thermal conductivity, Superior catalytic nature

Platinum Plated Ti Anode è Reduces or eliminates secondary processes, such as grinding

Platinum Covered Ti Anode è Anode geometry remains constant over time, allowing consistent optimized plating results

Platinum Faced Ti Anode è Long operating life, very low maintenance, increased bath life

Platinized Ti Anode è Economical (low platinum requirements for layering / coating / plating)

Platinised Ti Anode è High dimensional stability and load resistance.

Platinum Deposited Ti Anode è Good current distribution and Light weight

Platinized Titanium & Niobium Anode (Dimensionally Stable Anode)

Project Details:-

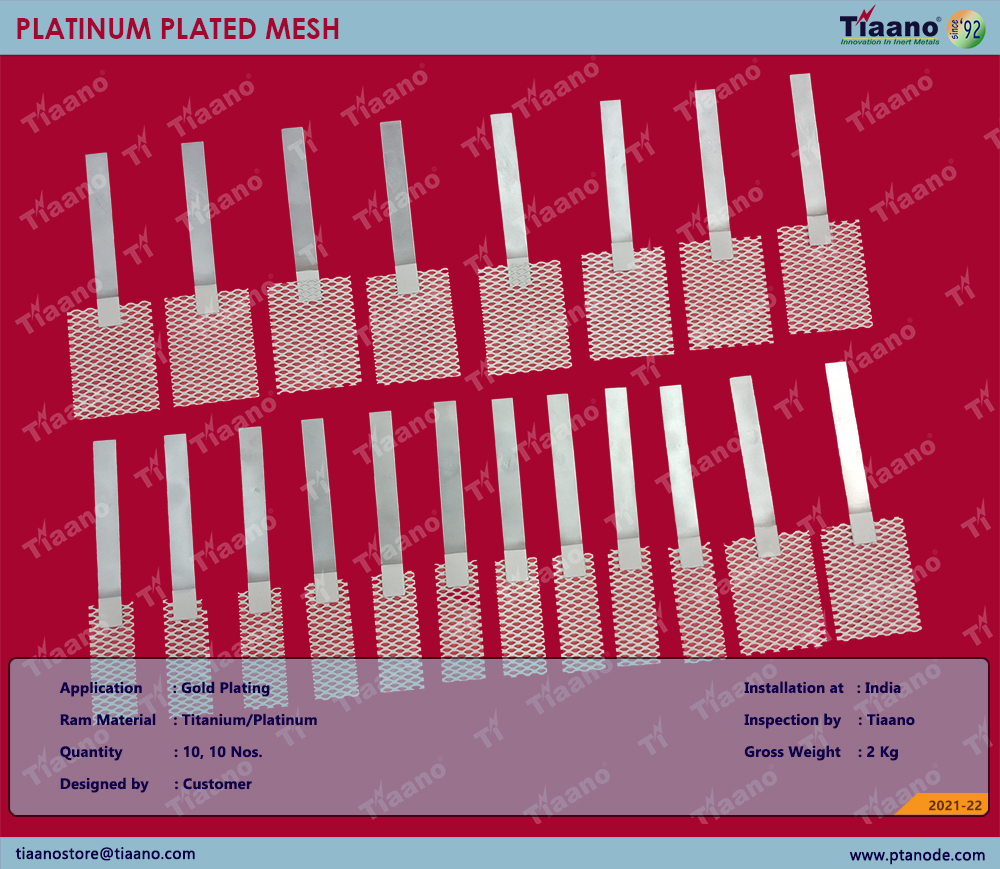

Tiaano: Manufacturer and Supplier of Platinum Plated Titanium Mesh Anode.

Anode: Electrolysis mesh Anode, Electro Plating Mesh Anode, Platinum Plated Mesh Titanium Anode, Titanium Expanded Mesh Anode

Application: Electro Chemical, Electrolysis, Electro Plating

Installation at: India,

Inspection by: Tiaano.

You may refer more details from here:-

Facebook Page, Instagram Page, Twitter Page, Pinterest Page